Manufacturers today are part of a global supply chain, sometimes specializing in one product or process. In a vast supply chain made up of contract manufacturers, suppliers, warehousing providers, and distribution specialists, labeling is the common language that allows every link in the supply chain to work together.

Manufacturers who have multiple upstream suppliers understand that labels on incoming goods must be accurate. Supplier labeling is a critical component of an efficient supply chain, and a unified supplier labeling system can have a big impact on overall efficiency and the bottom line. Read this blog to learn how centralizing your labeling can create easier labeling within your supplier network, reduce costly labeling errors, and make your company more lean.

Companies without a unified supplier labeling system are likely managing a hodgepodge of label files, data, and software.

All the above supplier labeling scenarios can lead to inaccurately labeled products, resulting in expensive and unnecessary supply chain bottlenecks.

Inaccurate supplier labeling causes significant inefficiencies in the inventory receiving process. An inefficient process means more time, space, and labor are required to manage incoming inventory.

With a unified supplier labeling system, companies experience much lower risk for labeling errors from their suppliers. The best part? No local software installations!

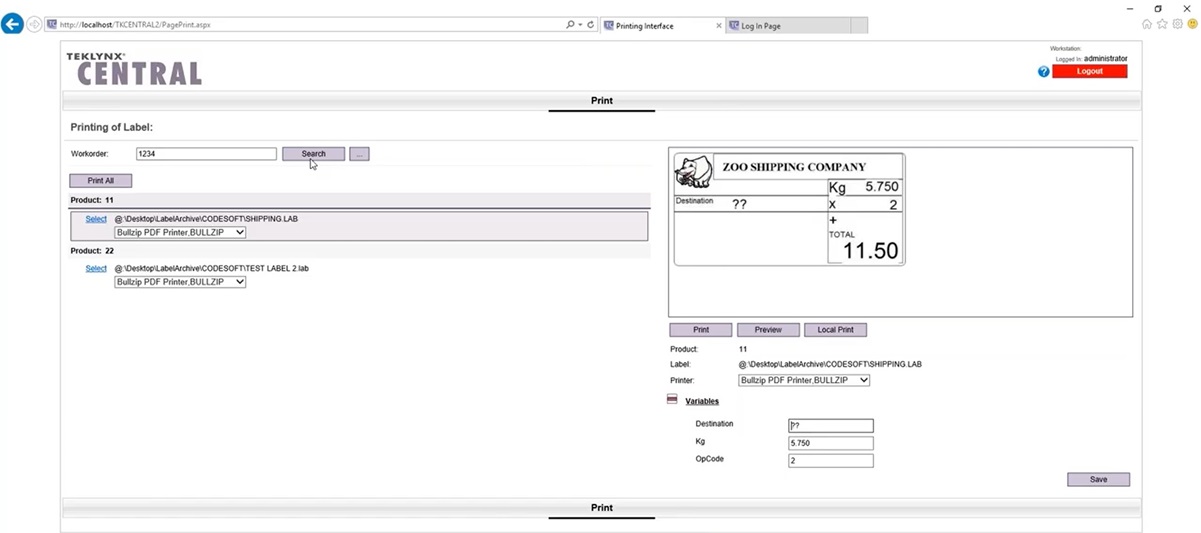

The supplier labeling system is centrally managed by your company. It can be enabled on-premise or in the cloud. Web-based label printing portals are published and can be branded with your company’s logo. Each supplier has secure access to approved label templates that automatically pull in real-time data from your business system!

The best way to modernize your supplier labeling is to implement a unified supplier labeling system. TEKLYNX CENTRAL label management solution from TEKLYNX provides an easy-to-manage all-in-one solution. With modules for label design, label security, web browser-based label printing, and label print automation, TEKLYNX CENTRAL meets manufacturers’ needs for supplier labeling and helps companies around the world barcode better.

Ready to learn more? Get in touch with a supplier labeling expert at TEKLYNX today.

Jenna Wagner, Global Marketing Director, is a successful strategic marketing executive with over 20 years of marketing experience in software technology and consulting services. She is a creative, dynamic, results-driven leader who possesses a passion for developing her teams. She leverages her deep understanding of the solutions and industries she serves to deliver impactful customer value throughout the global supply chain to help organizations barcode better.

Imagine painting a room and gathering supplies. You wouldn’t want to stop at three separate stores for your paint, primer, and brushes. It’s more convenient and efficient to stop at a store that carries everything you need, right?

READ MORE

When it comes to your barcode labeling software solution, implementing lean labeling and continuous improvement principles to your labeling environment reduces waste in label printing and saves you money.

Barcode labeling is a critical aspect of business operations to get your products to the right place at the right time. When it comes to improving operational efficiency, manufacturers regularly review key performance indicators like cycle time, on-time delivery, and customer return rate.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.