If you are using an Excel spreadsheet or other database (such as Access, SQL, or a full ERP system) to manage your business and product data, there's an easy way to eliminate manual processes from your label printing process! Most pain points in labeling processes stem from having too much room for human error and a lack of automation. Printing labels using your Excel data can help you save time, money, and maximize your efficiency.

Manual processes suck. Manual label printing processes without database connections look something like this:

A manual process is inefficient and prone to errors. The more data fields that need to be manually populated, the more room for error. If a mistake is made, you either have to manually go back in and fix it, or worse, you don't catch it until later after substantial damage is already done. This can waste time, resources, and money. This process can also be inefficient when a new product is released, and you have to create a new label. Instead of starting from scratch, you can input the new product’s information into your Excel spreadsheet and it’ll automatically be a part of your label printing system. It’s data management instead of label management.

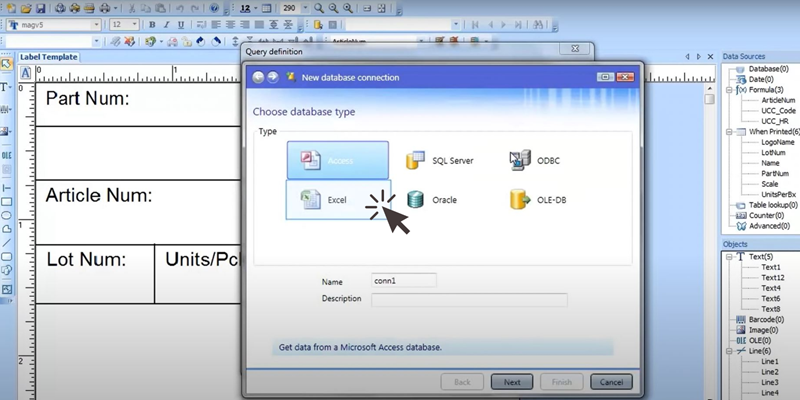

Database connections are a feature in TEKLYNX label design software that enable label templates to pull variable data in from an existing database. Excel spreadsheets can be considered a simple database, and as businesses grow and become more complex, they might graduate to a full database software such as Access. Database connections allow you to select a key data element (such as the part number or order number), and all other data is automatically populated on the label. Instead of maintaining hundreds of separate label files, you can create a handful of label templates that use Excel spreadsheets to print variable data.

Here's an example of using database connections to print variable data on nutrition facts labels.

That’s it! Once this connection is made, you can use this saved query on other label templates if the same information needs to be used elsewhere.

The Real Good Life is a meal delivery service in Milwaukee, Wisconsin. Since 2016, they have been serving the Greater Milwaukee area with nutritious, delicious, and cost-effective meals delivered right to their customers’ doors. When business started growing more, they ran into some roadblocks with their current labeling process. Their manual, handwritten labeling process was time consuming and produced costly labeling errors. The team at The Real Good Life was looking for an in-house label printing solution that could eliminate manual processes and accurately print their food and delivery labels from their Excel spreadsheet.

The Real Good Life is a meal delivery service in Milwaukee, Wisconsin. Since 2016, they have been serving the Greater Milwaukee area with nutritious, delicious, and cost-effective meals delivered right to their customers’ doors. When business started growing more, they ran into some roadblocks with their current labeling process. Their manual, handwritten labeling process was time consuming and produced costly labeling errors. The team at The Real Good Life was looking for an in-house label printing solution that could eliminate manual processes and accurately print their food and delivery labels from their Excel spreadsheet.

After collaborating with the team at TEKLYNX, The Real Good Life decided to go with LABELVIEW, a robust barcode label creation and integration software that checked all their boxes for an in-house label printing solution. “Now that we have LABELVIEW, it takes a matter of seconds to print labels,” stated Maggie Joos, owner and founder of The Real Good Life. “If we have a new product that needs to be entered into the database we simply open an Excel spreadsheet, add the data, and it’s ready to go.” With their newly implemented label printing software, The Real Good Life successfully eliminated their old labeling process of manually entering information on every product label, while simultaneously gaining efficiency with an easy-to-use barcode label design solution with little to no IT involvement. Now, The Real Good Life can focus on their goal of opening more locations and growing across North America.

Interested to learn more? Read the full case study.

Are you looking to eliminate manual steps in your labeling environment? Download a free 30-day trial of LABELVIEW barcode label software.

Travis Wayne is the Product Manager at TEKLYNX. Travis applies his 20+ years of IT and health sciences experience to empower businesses to streamline operations and barcode better by applying software and technology. He works to continually improve TEKLYNX strategic planning, product and project management principles, and cross-functional communications. When not working, he enjoys many outdoor activities with his wife and two children.

One of manufacturing's biggest fears is a product recall - not only because of the potential for bad PR, but because of the wasted product, money, time, and potential safety risks for the users of their products.

READ MORE

Without change there’s often no room for innovation or improvement.

READ MORE

We all know the saying, “You can’t have your cake and eat it too.” I am here to tell you that with TEKLYNX 2019 and newer products, it will feel like you can! Prior to TEKLYNX 2019 products, customization within the label print form was not possible.

READ MORE

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.