Thermal printing is an extensively used and mature technology that is extremely reliable, but print issues can still occur when printing labels. Manufacturers depend on thermal printing for product identification, dosage information, voltage currents, use-by dates, batch information, model and serial numbers, to name a few. Billions of product identification labels are printed each year and the supply chain, downstream assembly processes, and consumers, are all dependent on the accuracy of the information printed.

Learn about software for Printronix Auto ID Printers

By leveraging automatic label inspection technologies, you can inspect every label as it is printing and prevent critical labeling errors that can cost you time and money.

There are numerous variations of label printing issues, at many different levels, that can arise at any time and slow down production, waste time, and cost money.

At the printer level:

At the network level, networks go down and power outages occur, jeopardizing the integrity of data and causing duplicate labels, ‘lost’ labels, and unnecessary or uncontrolled reprints.

At the software level:

Many labeling errors have the potential to cause issues in the production process. Manufacturing companies are quickly seeing how critical it is to adopt technologies that automate the inspection of labels at the time of print to ensure they can meet the rise in demands for speed, quality and compliance.

How automatic label inspection technologies help with label compliance

How automatic label inspection technologies help with label compliance

Inspection of labels is essential to adhere to contractual supply agreements and regulatory compliance requirements – one incorrect or defective label can lead to total delivery rejects and chargebacks, and at worst, can lead to foreclosure by regulatory authorities for repeated non-compliance.

As anyone working in regulated industries knows, compliance requirements can be demanding and onerous. Compliance requirements such as those mandated by the U.S. Food & Drug Administration (FDA) include process control, strict batch reconciliation, user access control, and audit trail history. Compliance regulations also require that accurate and correct data is printed and recorded without duplicates, along with the correct market territory information.

There have been so many advancements in integrations and software technologies to improve how to manage to compliance labeling.

Real-time automated label inspection technology can capture and quickly resolve all the complex myriad of issues outlined thus far.

Inspecting labels does not just ensure print quality and data compliance, but it also:

Inspecting labels does not just ensure print quality and data compliance, but it also:

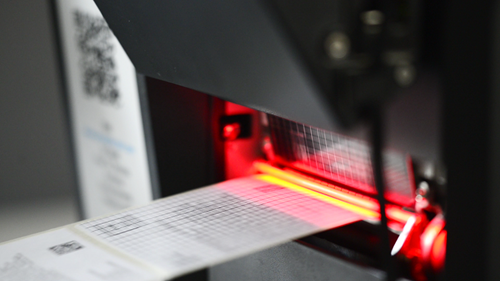

With innovative product solutions such as the Perceptor PTXL software with TSC Printronix Auto ID thermal printer and integrated ODV-2D camera, you now have real-time inspection of labels, with the ability to overstrike and destroy non-compliant, duplicate, or poorly printed defective labels….all at print speeds of up to 6” (150mm)/second.

These barcode verification technologies, combined with TEKLYNX CODESOFT barcode label design and TEKLYNX LABEL ARCHIVE label security and traceability software, maximize the full barcode process of design, approval, security, control, print quality, barcode verification, real-time label inspection, and reporting/visibility.

By design, Perceptor PTXL will hold the printing process to prevent unauthorized labels from being printed and when running, check printed labels in real-time for barcode verification, data and human readable content, print blemishes, duplicate labels, and ISO data content validation to UDI, GS1, and IUID for the medical device, pharmaceutical, life sciences, and aerospace & defense industries.

With cloud-based technology, all devices can be networked globally for authorized users to share the same inspection templates and record data to one global database where performance metrics and Microsoft PowerBI can analyze large data to help drive further efficiency gains.

With the adoption of automatic label inspection technology, increased processing power, improvements in OCR algorithms, faster IT infrastructure, and cloud-based solutions, manufacturers can more easily control the print process and avoid poorly printed, defective, or duplicate labels from being released into the supply chain, or risk of non-compliance in regulated markets.

Learn more about end-to-end barcode verification technology with TSC Printronix Auto ID and TEKLYNX.

Learn more about Perceptor PTXL inspection technologies and its full list of features. Information about TSC Printronix Auto ID printers can be found at www.tscprinters.com.

Mark Worlidge is the Founder, Owner, and President of InterVision Global Group, a well-established and respected machine vision inspection solution provider. Mark has been advising, selling, and supporting 2D DataMatrix coding and verification solutions for 25 years. He is extremely experienced in the deployment of print quality verification systems across all vertical sectors. Using his detailed understand of the market needs, he designed Perceptor PTXL, an innovative label inspection and code verification solution that is unrivalled in terms performance and capability. Mark’s passion is sailing, and when not working, you will often find him enjoying a sail with family and friends.

Compliance labeling is critical for manufacturers and distributors in many industries. Managing compliance labeling doesn’t need to cause headaches when you use a robust and reliable enterprise labeling system. Following these key principles will set you up for compliance labeling success.

READ MORE

As our world moves towards a digital transformation, automation is a crucial tool for a thriving business. By automating processes, companies can make their workflows faster and more efficient, enabling them to do more with less. This blog will go over how to automate your label printing and how TEKLYNX can help in providing solutions.

READ MORE

As the world is becoming increasingly digital, cloud technology is becoming more prevalent in our daily lives and in our companies. People stream their favorite shows through the cloud, facilitate business meetings through the cloud, and share important company files and documents in the cloud. So why not store your barcode data and labels in the cloud, too?

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.