Выберите ваш регион и язык для обеспечения максимального удобства при использовании веб-сайта

Выберите ваш регион и язык для обеспечения максимального удобства при использовании веб-сайта

Quality assurance (QA) is critical in manufacturing to ensure safety for employees and consumers of the product being manufactured.

In highly-regulated industries like medical device manufacturing, pharmaceuticals, and life sciences, regulatory authorities like the United States Food & Drug Administration (FDA) and the European Union (EU) have guidelines related to process validation to confirm a company’s processes will result in reliable outputs and meet all necessary quality standards.

Learn about TEKLYNX Validation Accelerator Pack

Process validation involves meticulous attention to detail and documentation for every step in the process of manufacturing as proof that those steps have been tested and validated to ensure quality outputs. This includes the process of manufacturing a product, like a medical device, as well as processes related to software systems like barcode label design and printing.

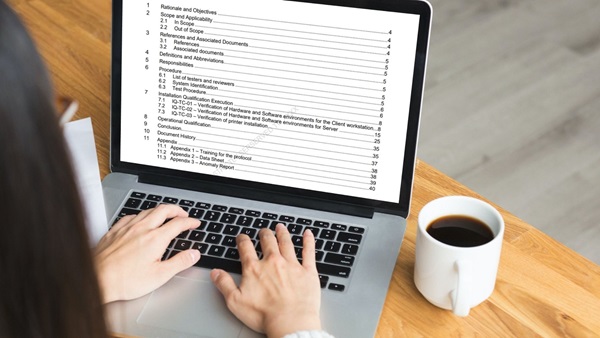

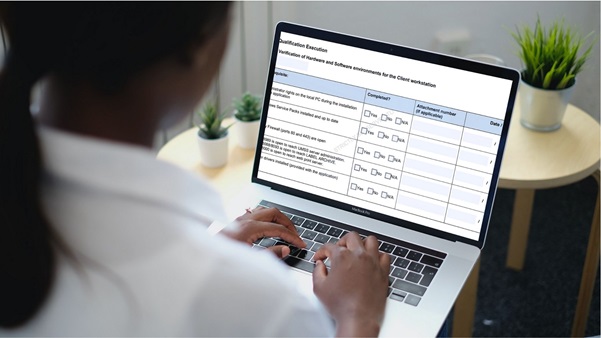

This is done through protocol test scripts for software validation through Installation Qualification (IQ), Operational Qualification (OQ), and Performance Qualification (PQ) protocols. Read this blog to get answers to the most common questions on the role of IQ OQ PQ in labeling system verification and validation.

The purpose of process validation for labeling systems is to establish documented evidence that the software is correctly installed, operates according to requirements, and performs safely. It also demonstrates that the manufacturing process, under normal operating conditions, will consistently produce conforming products and outputs.

IQ, OQ, and PQ are sequential activities that manufacturers need to carry out to validate their manufacturing processes.

In each phase of the validation process, documents are compiled with detailed results of each qualification test.

Validation requirements are most common in highly regulated industries where quality and safety standards, if not being met, could result in serious injuries or death. The most common industries where life is at stake, and where validation is required, are:

These industries face many labeling regulations that have been established to help protect safety. Each of the regulations outlined below have processes and steps that need to be outlined and included with labeling system validation as part of IQ, OQ, and PQ:

Features and processes within the labeling system must be defined, tested, and have a “pass” status to validate compliance with these requirements.

Software validation helps to ensure business continuity. It is a critical tool used to assure the quality of device software and software automated operations such as labeling. Software validation can increase the usability and reliability of the device and label, resulting in decreased failure rates, fewer recalls and corrective actions, less risk to patients and users, and reduced liability to device manufacturers.

Labeling system validation also forces the requirement of having documented process and procedures which can be used as a guide for ease of training as well as a reference tool for help in disaster recovery, if ever needed.

Persons subject to the medical device quality system regulation may include:

Manufacturers in highly regulated industries are often required to face (and perform) validation every three years. There are also a variety of events that may occur externally or internally that require validation documentation to be updated and/or inspected. Some examples of “events” that may trigger the need to perform IQ OQ PQ testing and validation include:

Due to the complexity of software, a seemingly small local change may have a significant global system impact. When any change (even a small change) is made to the software, the validation status of the software needs to be re-established. Whenever software is changed, a validation analysis should be conducted not just for validation of the individual change, but also to determine the extent and impact of that change on the entire software system.

Based on this analysis, you should then conduct an appropriate level of software regression testing to show that unchanged but vulnerable portions of the system have not been adversely affected.

Validation and proof of quality outputs with safe processes is required to pass the audit and avoid risk of fines or, worst-case, production shutdowns.

An inspection of your operation may be completed by the FDA for a variety of reasons, such as a routinely scheduled inspection or in response to a reported problem. It is in your, and your company’s, best interest to ensure you fully understand FDA’s inspection procedures in advance of any visits.

When you are faced with an inspection:

After the investigation is completed, the inspector will share any significant findings and concerns with your management and will leave a written report. If you can make any corrective actions or procedural changes while the inspector is present, you should do so.

* We recommend you contact FDA directly to gain a full understanding of what is required by you and on what you should expect when faced with an inspection.

Whether you are a new company performing labeling system validation for the first time, or a long-established manufacturing company who is experiencing changes within your labeling system, there are a few options to work through IQ OQ PQ testing documentation and validation.

TEKLYNX customers in pharmaceuticals, life sciences, and medical device manufacturing often need a label traceability solution that helps them comply with 21 CFR Part 11. LABEL ARCHIVE label traceability software from TEKLYNX enables electronic signatures, provides version control, and offers visibility into the design, approval, and printing of a label. To build on these features while also allowing for centralization and standardization of labeling across the enterprise and all locations, companies turn to TEKLYNX CENTRAL enterprise label management solution for maximized control, automation, and compliance.

Because of the popularity and necessity of these label management applications in the industries that require software validation, the TEKLYNX VAP is available for purchase with CODESOFT + LABEL ARCHIVE or TEKLYNX CENTRAL labeling applications and is developed to dramatically accelerate validation of labeling system processes, saving weeks (if not months) of time and resources. TEKLYNX is here to help.

Nick Recht is the Sales Manager for the Americas region at TEKLYNX RFID and barcode label solution provider. He leverages his passion for using technology to add value to businesses and his 15 years of AIDC experience to help organizations of all sizes barcode better. When he is not working, he is driving one of his daughters to a practice of some sort or doing a project around the house.

The medical device industry is one of the most highly regulated industries out there.

READ MORE

Lately, there’s been quite the buzz around the European Union Medical Device Regulation or better known as, EU MDR. The EU MDR is a priority for all companies in the medical device industry that distribute products in the EU and will officially take effect on May 26, 2021. This regulation has more need for data management and complex assessment procedures than the regulation it replaces (MDD – Medical Devices Directive).

Compliance labeling is critical for manufacturers and distributors in many industries. Managing compliance labeling doesn’t need to cause headaches when you use a robust and reliable enterprise labeling system. Following these key principles will set you up for compliance labeling success.

READ MORE© Авторские права 2025 TEKLYNX CORPORATION SAS. Все права защищены.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.