Selecione sua localização e idioma para obter a melhor experiência de site da web

Selecione sua localização e idioma para obter a melhor experiência de site da web

In an industry that historically holds a high standard of quality for production and shipping processes, it’s essential for labeling to be consistent and accurate throughout the automotive supply chain.

Leaning on contract manufacturers to provide components, modules, or assemble entire vehicles lets companies focus on more critical strategic matters. But with contract manufacturers or original equipment manufacturers (OEMs), you typically have multiple suppliers or vendors working to complete a final product, meaning more stakeholders and more supply chain complexity.

Barcode labeling is the common language that allows every link in the automotive supply chain to work together efficiently. This blog will go through the importance of barcode label quality (and how to ensure it), centralizing control of barcode labeling and creating a supplier network to do so, and where to get started.

Read an automotive industry case study

According to Forbes, the average automotive manufacturer loses $22,000 per minute when the production line stops and that quickly adds up. Overall, unplanned downtime costs industrial manufacturers as much as $50 billion a year.

Modern car production lines in use today are not much different than the basic Ford systems of the past when you look at the very basics. Automobiles still go from station to station and worker to worker along a steady assembly line. If components, bins, or pallets aren’t where they need to be at the exact time they’re needed, a worker or station can’t finish a car to pass it to the next station and an assembly line stops, production is delayed, and revenue is lost.

Avoiding this starts even before pallets arrive at the receiving dock – it starts with those incoming shipments and pallets having accurate and readable barcode labels, so workers at the receiving dock know if a pallet needs to go to the warehouse or directly to the line. So, the importance of a barcode label is incredibly high – if it can’t be read, everything stops. Plus, bad barcode labels are not attractive to automotive manufacturers – they can result in fines, supplier audits, or canceled contracts.

LABEL ARCHIVE label security and traceability software and TSC Printronix Auto ID ODV-2D barcode verification and validation printers offer a solution to help reduce downtime due to incorrect, missing, or unreadable barcodes. ODV-2D printers enable suppliers to inspect every barcode automatically and integrates with LABEL ARCHIVE for full traceability of barcode verification. Every single barcode label that is printed has its barcodes scanned, verified, graded, and recorded in the LABEL ARCHIVE database.

Through barcode verification and traceability, suppliers can ensure their shipments are in accordance with guidelines for shipping/parts identification labels and contract manufacturers can rest easy knowing 100% of shipments from that supplier will arrive with high-quality barcodes.

Another way to make sure incoming labels adhere to guidelines and regulations? Centrally managing the labels suppliers use.

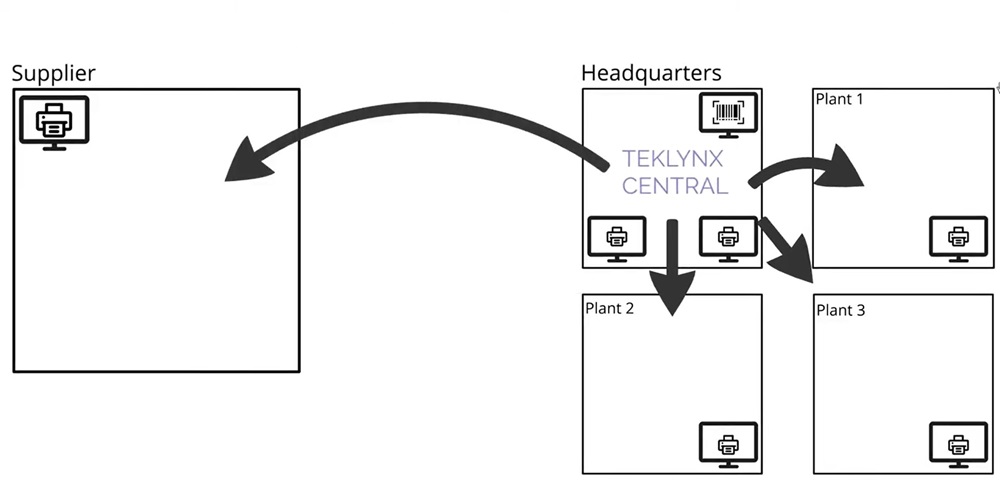

With TEKLYNX CENTRAL enterprise label management solution, labeling for automotive contract manufacturers who have a lot of suppliers or vendors can centralize control of barcode label printing to ensure both industry regulations and customer requirements are met, plus eliminate any need to send label files back and forth. With modules for label design, print automation, label security and traceability, and browser-based label printing, TEKLYNX CENTRAL meets contract manufacturers’ needs for supplier labeling.

The supplier labeling system is centrally managed from one location - for example, headquarters show in the image below - and can be hosted on-premise or in the cloud. Browser-based label printing portals are then published, so outside plants or suppliers can have secure access to approved label templates that automatically pull in real-time data from a business system for accurate printing.

Defined business processes can be enforced at every level, restricting access to only the printers, labels, and tasks a user needs to perform their job. And because no local software installations are required, new plants or suppliers can easily be added to the system without requiring IT support.

A controlled automotive supplier labeling system provides the security needed to ensure accuracy and quality of all incoming and outgoing barcode labels. And as automotive industry regulations change and customer or manufacturer requirements are updated, suppliers can immediately access updated (and approved) labels through their secure label printing portal.

TEKLYNX is the only barcode label design software developer to offer subscription licensing at a lower up-front cost and discounts available for multi-year licenses. Our software solutions help contract manufacturers, OEMs, and suppliers with all of their barcode labeling needs.

TEKLYNX is the only barcode label design software developer to offer subscription licensing at a lower up-front cost and discounts available for multi-year licenses. Our software solutions help contract manufacturers, OEMs, and suppliers with all of their barcode labeling needs.

Reach out to discuss current or ideal labeling processes and let us help you barcode better like we have for other customers in the automotive industry.

Nick Recht is the Sales Manager for the Americas region at TEKLYNX RFID and barcode label solution provider. He leverages his passion for using technology to add value to businesses and his 15 years of AIDC experience to help organizations of all sizes barcode better. When he is not working, he is driving one of his daughters to a practice of some sort or doing a project around the house.

Manufacturers today are part of a global supply chain, sometimes specializing in one product or process. In a vast supply chain made up of contract manufacturers, suppliers, warehousing providers, and distribution specialists, labeling is the common language that allows every link in the supply chain to work together.

READ MORE

When it comes to barcodes and their use on labels such as product, inventory, shipping, and case labels, quality is paramount. A poor-quality barcode label can result in delays in production, returns, chargebacks, poor customer experience, and potentially recalls – no company wants to face those headaches. Thankfully, there are many options and solutions to help improve the quality of barcode labels and safeguard your business’ labeling processes.

READ MORE

Integrating label printing systems with SAP is a guaranteed way to decrease labeling errors and maximize ROI while also speeding up your label printing process.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. Todos os Direitos Reservados

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.