Wybierz swoją lokalizację i język, aby korzystać z najlepiej przystosowanej strony internetowej

Wybierz swoją lokalizację i język, aby korzystać z najlepiej przystosowanej strony internetowej

When you need to print a label, how long does it take to find the correct file, populate the correct data, and start the print job? If you’re not leveraging the power of variable data on smart label templates, it could take several minutes just to find the right label file! Multiply those minutes by the number of print jobs and you end up negatively impacting your throughput.

In this blog, you’ll learn smart labeling strategies to minimize the number of label files you manage and optimize data entry with variable data fields.

Label design is critical in every industry with a physical product. The label is how information is communicated between suppliers, customers, distributors, retailers, and end users. For businesses with multiple product variants or product lines, label files can quickly get out of hand as they create a new file for each product variant or new product.

Minimizing label files by using smart label templates with variable data can be a game changer for these organizations. Instead of spending time wading through hundreds (or thousands!) of label files and manually entering data, users can simply scan, key in, or select a record and print. Let’s get started.

Variable data refers to information that can change from one label to the next. Unlike static data, which remains constant across all labels, variable data changes based on a user selection or input. Variable data can be sourced from databases, spreadsheets, or external data files and is integrated into a smart label template.

A simple example of variable data is addresses on shipping labels. The name, street address, city, state, postal code, and country are all variable data fields placed onto a smart label template. Each database record represents a person. As you change database records, the data on the label changes.

If the address data was static, the print user would have to create a new label and type in each address manually. Manual data entry is slow, leads to mistakes, and results in shipments returned to sender!

Variable data is used in countless ways across every industry.

Food & Beverage: Variable data allows for the creation of food & beverage labels that are specific to each product variant, including different product lines, different flavors, nutritional information, and expiration dates.

Pharmaceutical & Medical Device: Accurate batch numbers, dosage instructions, patient information, and unique device identifiers are critical in the healthcare and life sciences industry.

Manufacturing & Logistics: Variable data is essential for labeling products with unique serial numbers, manufacturing dates, and other traceability information. This aids in inventory management, quality control, and recalls if necessary.

Automotive & Aerospace: Variable data is critical for labeling parts and components with specific information, such as part numbers, manufacturing dates, and compliance details. This ensures that each component can be identified and tracked throughout the supply chain.

Retail & Consumer Goods: Retailers often use variable data for product labels that include pricing, promotions, and regional variations.

Wine & Spirits: Wineries and distilleries use variable data for creating unique labels for each bottle, including details about the grape harvest, alcohol content, and production location.

Cannabis: Countries and states that have legalized cannabis have strict cannabis labeling requirements to protect consumer safety. Variable data on cannabis labels can include laboratory testing data, strain, type, weight, and THC or CBD levels.

In these diverse industries, the use of variable data is not just a convenience but a necessity, enabling organizations to meet regulatory requirements, enhance efficiency, and deliver customized solutions to their customers.

There are two major benefits of using variable data on smart label templates: efficiency and accuracy.

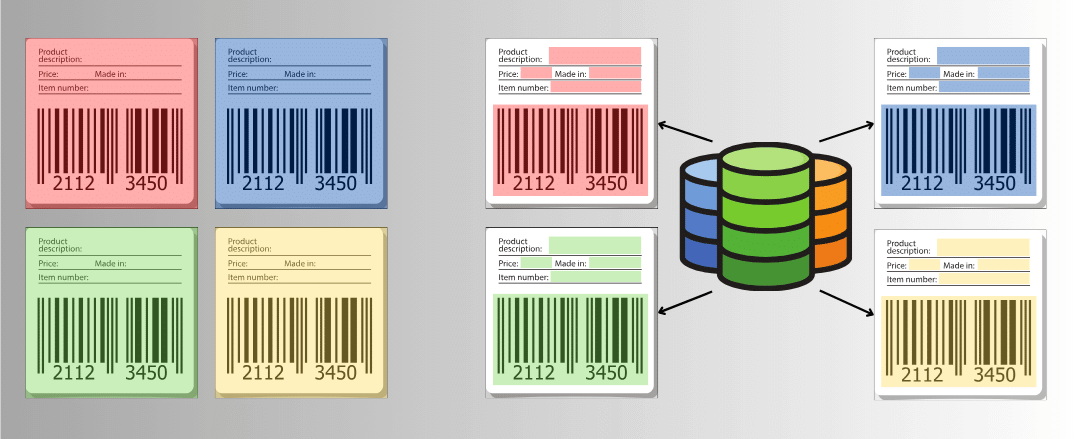

Without variable data on labels, companies often end up with hundreds of label files, each containing different static information. Print users have a real challenge to find the correct file to open and print. When you need to update a common element, such as a logo or business address, changing every single static file can take hours or even days!

Using variable data allows you to consolidate all similar labels into one template and pull in data from a database or spreadsheet. Reducing the number of label files you manage saves time for both label design users and print users.

When print users have to choose the correct label file to open, it’s easy to make a mistake and print the wrong label. Similarly, if static data needs to be updated for each label print job, it’s only a matter of time before a typo ruins a batch of labels.

When variable data is pulled from a database or business system, you can rely on the accuracy of the system. Critical data, such as serial numbers, lot numbers, ingredients lists, expiration dates, and shipping addresses, are much more likely to be accurate, reducing the risk of labeling errors.

Use these data-driven label design strategies to successfully implement variable data on your labels.

Whether your data resides in a simple spreadsheet, or your company uses a robust database, you can connect that data to your label design software.

Common spreadsheets include Microsoft Excel and Google Sheets. Common databases include Microsoft Access, Oracle, and SQL. Common business systems include SAP, Oracle, Microsoft Business Central, Global Shop Solutions, NetSuite, JD Edwards, and many more.

Use your label design software to set up data sources – where your variable data will come from. In addition to databases, the following sources can be used:

Tagged text management is a type of formula that can be used to stylistically highlight predefined words in a text field. It is particularly useful for highlighting allergens in ingredients statements, which is a requirement for food sold in the European Union.

An image file listed in your database can be displayed on the label file. Each database record can reference a different image. This feature can be useful for product variations such as different flavors, scents, or colors.

For even more advanced variable label data, tools such as VBScript can streamline your labeling process. Keep in mind that features like VBScript are highly technical, and you can request TEKLYNX Professional Services for assistance.

To get your variable data onto your labels in the right place and format, you need label design software.

At TEKLYNX, we offer a variety of label design software solutions, and all include support for variable data.

CODESOFT advanced label design software provides the most robust variable data features:

CODESOFT includes over 4,000 native printer drivers to print accurately to virtually any label printer.

Print automation software integrates variable data onto your labels and automatically initiates print jobs without manual interaction.

You can automate label printing using SENTINEL, which runs in the background, so your users never even have to think about it! Here are some of the common methods used to automate label printing with variable data integration:

When variable data is sent programmatically, it eliminates the risk of errors due to manual data entry. Plus, it’s much faster!

LSI Industries, a lighting, graphics, and technology manufacturer, had built up a vast repository of static label files over the years – over 6,000 of them! Maintenance and updates were a serious burden on resources, with six employees responsible for design and management.

LSI Industries selected SENTINEL to integrate with its JD Edwards ERP system and automate labeling printing. “Our primary goal was to eliminate the manual maintenance of a growing number of static label files,” explained Tom Cantrell, Manager of Product and Manufacturing Support at LSI Industries.

Integrating the two systems meant that LSI could eliminate their 6,000+ static label files and replace them with database-driven smart label templates. File maintenance time was reduced by 80%, allowing staff to focus on other mission-critical activities.

Download the full LSI Industries case study.

If you’re just getting started with label design, use these smart labeling strategies to keep the number of label files you manage under control. Need help understanding a variable data feature in CODESOFT? TEKLYNX Customer Support is here to help.

If you have hundreds or thousands of static label files, the idea of updating them to use variable data can seem overwhelming. Luckily, TEKLYNX offers services to redesign and consolidate your labels into a manageable set of smart label templates.

Whether you use TEKLYNX label design software or another solution, our team of label design experts can convert and consolidate any type of label. Simply provide the files and outline the data sources, and you’ll receive efficiently designed labels ready to print. Request TEKLYNX Professional Services.

Variable data is a critical strategy for efficient label design. Pulling variable data from business databases onto smart label templates makes labeling more efficient and accurate. If you’re ready to improve your labeling, get in touch with us today.

Travis Wayne is the Product Manager at TEKLYNX. Travis applies his 20+ years of IT and health sciences experience to empower businesses to streamline operations and barcode better by applying software and technology. He works to continually improve TEKLYNX strategic planning, product and project management principles, and cross-functional communications. When not working, he enjoys many outdoor activities with his wife and two children.

Leveraging your existing Excel spreadsheets in your label printing process can help you save time, save money, and maximize your efficiency.

READ MORE

As the world is becoming increasingly digital, cloud technology is becoming more prevalent in our daily lives and in our companies. People stream their favorite shows through the cloud, facilitate business meetings through the cloud, and share important company files and documents in the cloud. So why not store your barcode data and labels in the cloud, too?

As our world moves towards a digital transformation, automation is a crucial tool for a thriving business. By automating processes, companies can make their workflows faster and more efficient, enabling them to do more with less. This blog will go over how to automate your label printing and how TEKLYNX can help in providing solutions.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. Wszystkie prawa zastrzeżone.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.