Selecteer uw locatie en taal voor de beste website-ervaring

For chemical manufacturers, importers, distributors, and employers in the US, Globally Harmonized System of Classification and Labeling of Chemicals (GHS) compliance is a requirement. Shipping chemicals without proper GHS labeling or labeled under old Hazard Communication Standard (HCS), can result in fines and penalties against your business. According to Occupational Safety and Health Administration (OSHA), penalties can start at $16,131 and exceed $161,000 per violation. Improperly labeled chemicals can also potentially result in injury or death, making GHS-compliant labeling procedures critical to supply chain operations.

Within this blog, learn about the importance of remaining complaint with GHS labeling standards and how to create GHS compliant labels with TEKLYNX label design software.

Learn more about GHS chemical labeling

GHS is an internationally agreed-upon standard managed by the United Nations that was set up to replace the assortment of hazardous material classification and labeling schemes previously used around the world.

The Final Rule states that all chemical manufacturers, importers, distributors, and employers must comply with all modified provisions. Distributors can no longer ship chemicals labeled under the old HCS. Employers must update alternative workplace labeling and hazard communication programs and provide additional employee training for newly identified physical or health hazards.

On May 20, 2024, OSHA issued a final rule that updates the HCS to align with the seventh revision of GHS and better protect workers. The updated standard requires labels on small packaging to be clearer and easier to read and allows workers and first responders to react faster in emergencies. The updates took effect on July 19, 2024.

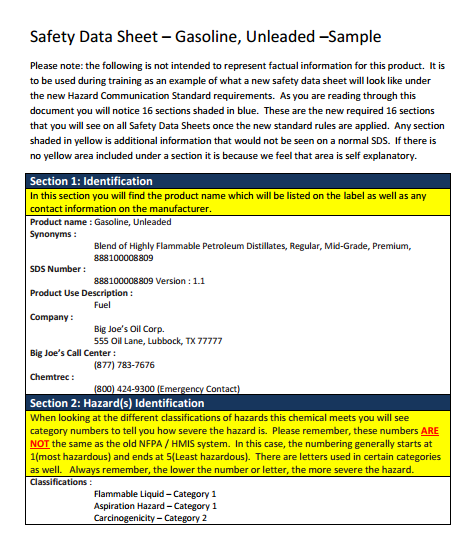

Updating your SDS, formerly known as Material Safety Data Sheets (MSDS), is a crucial component of GHS compliance. SDS are kept on file to provide detailed information about each chemical used, produced, or sold by your company. This is most important to employees who work with the chemicals because they are made aware of the harmful chemical exposure and what personal protective equipment they will need for the job.

A GHS compliant label contains six required elements to help aid in the identification of chemicals and their hazards:

Example of a GHS-compliant label made in CODESOFT barcode labeling software

Now that you know what GHS-complaint labels are and what they must contain, let’s breakdown how to create GHS compliant labels.

Creating GHS-compliant labels doesn’t have to be complicated - with the right tools and technology, printing compliant GHS labels can be as simple as the push of a button! Let’s break it down with TEKLYNX labeling software.

With TEKLYNX advanced RFID and barcode label software, CODESOFT, you can set your business up for success by:

Create your own GHS labels by downloading a free 30-day trial of CODESOFT. TEKLYNX also offers a GHS label sample to help you get started creating compliant GHS labels. If you encounter any issues, TEKLYNX Customer Support is available to help you throughout your trial.

BeanTown Chemical achieved complete GHS compliance with over 7,000 products and over 5,500 unique chemicals with the implementation of CODESOFT. “Labeling is one of the most daunting projects you can have in the business. There are a lot of regulations,” states Barry Singelais, President of BeanTown Chemical. “It is very difficult to find a product that will allow you to do it efficiently and affordably because there are certain requirements for color, where data should be placed, what the pictograms should look like and how many to display, depending on the hazard. There are so many individual components of GHS. Many packages we found could do 10 out of 12 of the components, but we weren’t finding a lot that could do all 12,” Singelais said. “CODESOFT could, and that’s why we chose it.”

Often, the need for a single, unified solution to handle label design, approval, printing, and reporting arises.

With TEKLYNX CENTRAL, you can seamlessly comply with GHS label regulations with maximum traceability, accurately classified chemicals, and HCS elements for all types of labels and Safety Data Sheets. You can also:

Shepherd Color Company implemented TEKLYNX CENTRAL and was able to improve GHS-compliant labeling efficiency and accuracy while reducing print time by 10%. “The implementation of the new labeling system inspired us to take a blank slate approach to our sample department’s entire labeling process. It facilitated our move to a lighter weight, more durable and eco-friendly shipping container, saving us shipping costs on every sample order. With over 10,000 sample orders a year you can see how those savings quickly add up,” states Diana McDonough, Senior Developer, Shepherd Information Systems.

Saving money and reducing waste are two goals for manufacturers around the world, especially when it comes to their label printing process. It may sound easier to outsource your label creation, which is called a 2-step process, but that is not the case. Typically, with the 2-step process you pre-order labels in bulk and then print variable data in-house. If you are still using the 2-step process with your GHS-compliant labels, you’re probably ending up with labels that have mistakes like:

Your solution? On-demand color labeling. This approach allows companies to create smart label templates that incorporate variable data & images, so you can design and print GHS-compliant labels as you need them. This eliminates the risk of errors due to print misalignment that happens when you use pre-printed stock. Printing labels on-demand eliminates inventory of pre-printed label stock and associated label waste due to misprints, which can result in total label cost reduction. Epson's line of ColorWorks label printers work seamlessly with TEKLYNX native printer drivers that enables true WYSIWYG (What You See Is What You Get) on-demand color label printing. With on-demand color printing you’ll end up with:

Now’s the time to start creating and managing your GHS-compliant labels. Have questions? Get in touch with TEKLYNX to find out which GHS-compliant labeling solution is best for your business.

Design GHS Labels Manage GHS Labels

Travis Wayne is the Product Manager at TEKLYNX. Travis applies his 20+ years of IT and health sciences experience to empower businesses to streamline operations and barcode better by applying software and technology. He works to continually improve TEKLYNX strategic planning, product and project management principles, and cross-functional communications. When not working, he enjoys many outdoor activities with his wife and two children.

Color labeling is not a new phenomenon. Manufacturers have long understood the value of incorporating color onto their labels. From branding and marketing to product identification, the opportunities color can provide are limitless.

READ MORE

Compliance labeling is critical for manufacturers and distributors in many industries. Managing compliance labeling doesn’t need to cause headaches when you use a robust and reliable enterprise labeling system. Following these key principles will set you up for compliance labeling success.

READ MORE

Barcode labeling is a critical aspect of business operations to get your products to the right place at the right time. When it comes to improving operational efficiency, manufacturers regularly review key performance indicators like cycle time, on-time delivery, and customer return rate.

I'm very pleased to learn such a brilliant piece of information. I appreciate your hard work.

Reply© Copyright 2025 TEKLYNX CORPORATION SAS. Alle rechten voorbehouden.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.