Selecteer uw locatie en taal voor de beste website-ervaring

According to the Enterprisers Project, security must be a top priority for technology executives in 2022. Building a secure barcode labeling process is an important piece of a company’s security strategy that has a direct impact on the bottom line.

Mislabeling is one of the top causes of recalls in the United States, and labeling errors stem from gaps in labeling security. This blog will discuss ways to create a managed, controlled, and secure barcode labeling process leveraging better connections between people, software, and process.

Creating a more secure barcode labeling process starts with ensuring the right people have access to edit the right labels – and others don’t. A barcode labeling system without established user permissions is nothing short of a major security risk. No matter how thorough your label software training is, if the system allows any user to edit any label, it’s only a matter of time before a mistake is made.

Luckily, setting up basic user permissions is not difficult, and you can even leverage Windows Active Directory for single sign-on, so users don’t need to memorize more passwords – creating a simpler and more secure process. Here are two ways to implement barcode labeling security through user permissions:

Barcode label software print-only licenses are exactly what they sound like: software registered under this license type only allows the user to print. All editing features are disabled, and a form is used to gather print-time data without editing static label data. All TEKLYNX label design software products offer a print-only license option.

A print-only license should always be used alongside a full-featured license assigned to the user responsible for label design.

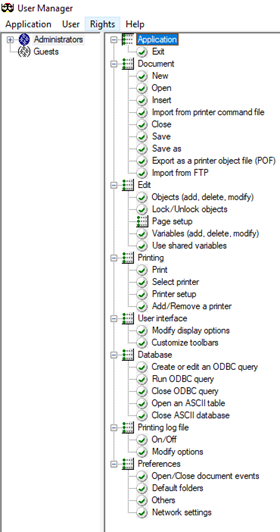

When you need more granular control over which features individual users, user groups, or departments are allowed to access, configure User Manager to meet your needs. User Manager is a feature of CODESOFT Enterprise label design software.

In User Manager, first create a new Profile. A Profile can have one or more user assigned and is beneficial when teams expand or change. Next, select the permissions you want to assign to this Profile:

Some examples of Profiles include:

Finally, assign Users to the appropriate Profiles using Windows Active Directory. Users can be added from a local or network location.

For the most effective security in your barcode labeling environment, implement a label security and traceability system. Label security and traceability software not only limits user permissions based on their role, but it enables traceability by tracking every label version, approval, and print job.

With a complete system dedicated to label security, you can:

LABEL ARCHIVE label security software from TEKLYNX offers all these benefits at a low cost.

For companies in the life sciences industries (medical device, pharmaceutical, healthcare, etc.), barcode labeling security isn’t a nice-to-have – it can have serious outcomes for patients and staff. This is why the United States Food & Drug Administration (FDA) and the European Union (EU) require system validation for technologies and processes used to manufacture medical devices and pharmaceuticals.

Label system validation is essentially thorough documentation that your labeling system is installed correctly, operates correctly, and performs as expected. Installation Qualification (IQ) protocols, Operational Qualification (OQ) protocols, and Performance Qualification (PQ) protocols are commonly referred to as IQ, OQ, and PQ. With IQ, OQ, and PQ validated, you can be confident that your labeling system is set up properly and securely, and that you’re familiar with all important security features.

Validating a system from scratch can be extremely time consuming. That’s why TEKLYNX offers a Validation Accelerator Pack (VAP) for CODESOFT + LABEL ARCHIVE or TEKLYNX CENTRAL. The TEKLYNX VAP includes the required testing procedures for validation of our software by life sciences companies.

Manufacturers who have upstream suppliers understand that labels on incoming goods must be accurate, but sharing barcode labels with external suppliers via email or file share websites creates an uncontrolled and non-secure labeling environment. Lax barcode labeling security for your suppliers can lead to outdated labels being used for shipments, inaccurate inventory, manual intervention, relabeling, or returns.

A secure supplier labeling system leverages user permissions, process traceability, and secure browser-based label printing. Supplier labels participate in the label traceability system, ensuring that only authorized users make changes, and those changes are approved via the defined workflow. Then, approved labels are made available to external suppliers via a secure webpage. Each supplier has their own username and password, so they only have access to their label files. Browser-based label printing ensures that only the most accurate, up-to-date data is printed on your supplier labels.

TEKLYNX CENTRAL is an all-in-one label management solution for secure barcode labeling. It can be hosted on-premise or in the cloud. Cloud hosting leverages all the security features of the cloud provider, such as Amazon Web Services (AWS).

Whether you want to start with print-only label design licenses, enforce user permissions, or centralize multi-location or supplier labeling, TEKLYNX is here to help you make your barcode labeling process more secure. Get in touch with a barcode labeling security expert today.

For more information, view our barcode labeling security infographic!

Anthony Bieniewski is the Operations and IT Manager at TEKLYNX. Anthony uses his 15+ years of experience in IT infrastructure and security to continue to move TEKLYNX forward with efficient and secure processes and tools. He also leverages that experience in mentoring and coaching TEKLYNX’s support team so that they can continue to pursue best practices when helping our customers barcode better.

In today’s day and age, you can track just about anything; when your Amazon package will be delivered, where your friends and family are located, and even your pizza delivery! But what about your barcode labels?

READ MORE

A common labeling challenge I’ve been hearing recently is the need to move toward a paperless label approval process. Instead of printing out sample labels, physically delivering them to each person in the approval process, and returning to the label design software to implement changes, companies are looking to digitally transform this process and make label approval paperless.

READ MORE

One of manufacturing's biggest fears is a product recall - not only because of the potential for bad PR, but because of the wasted product, money, time, and potential safety risks for the users of their products.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. Alle rechten voorbehouden.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.