Selecteer uw locatie en taal voor de beste website-ervaring

When it comes to the food and beverage industry, it is incredibly important to have the best label software in place to ensure efficiency, stability, and peace of mind throughout the supply chain. With dynamic labeling regulations, a need for visibility and traceability in the supply chain, and a constantly growing and evolving industry, your barcode labeling software should provide you with the functions and capabilities you need to succeed.

Today’s top food and beverage producers need to partner with organizations that understand their challenges and provide innovative tools and technologies to meet both their organizational goals and initiatives as well as regulatory requirements.

The need for greater visibility across the supply chain is leading companies to adopt centralized systems integrated with other technology. These new integrations should have the ability to automate manual processes, standardize your labeling environment, and be compliant to regulations that your business needs to adhere to. Businesses are working to remove manual data entry so as to avoid high operational costs and potential business risk stemming from labeling errors. Your labeling software should provide your business with full visibility at each stage in your process to mitigate risk and make sure you're always operating efficiently.

Below are food and beverage labeling regulations that many companies face as well as details on the best label software for the food and beverage industry:

The Product Traceability Initiative (PTI) is an industry-wide effort to improve efficiency and effectiveness of track and trace procedures throughout the produce supply chain, while also reducing the impact of potential recalls or similar problems. Whether you are a small community farming operation or a major produce supplier, it is essential to have PTI-compliant barcode labels.

When selecting a labeling software, food and beverage companies must ensure they are selecting a provider whose solutions allow you that kind of full visibility and traceability. Your labeling software should also have built in design wizards to assist in correctly displaying the required Global Trade Item Number, Batch/Lot Number, and Pack/Harvest Date in both human readable form and in machine-readable GS1-128 barcode. CODESOFT allows for the simple generation of accurate, PTI-compliant labels using the built-in formula to create the Voice Pick Code. CODESOFT also helps create PTI-compliant labels for fresh produce, where having full visibility and traceability from harvest to sale is incredibly important.

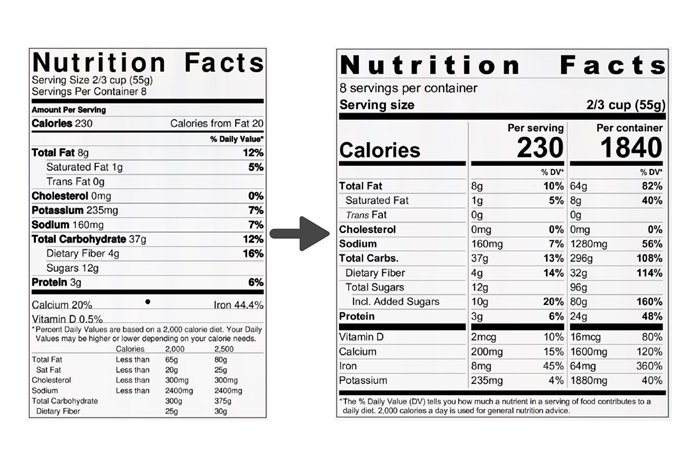

The US Food and Drug Administration (FDA) requires a Nutrition Facts label to be placed on all packaged food and beverages.

As of January 1st, 2020, food and beverage manufacturers with more than $10 million in annual food sales must comply with these new requirements, including a revamped label design that includes bold elements and larger fonts, updated list of nutrients and daily values required, and revised serving size and dual column requirements for certain package sizes.

These new requirements mean that when selecting the best label software for the food and beverage industry, you must ensure that you’re selecting a software solution that can adapt to different label formats, implement dynamic styling, and offer robust database connections to help you comply. The software should allow you to become immediately familiar with the interface and have a minimal learning curve.

Learn more in our Food Labeling eBook.

The Brewers’ Voluntary Disclosure Initiative encourages beer companies to voluntarily include a serving facts statement on their products, packaging, or websites.

The Serving Facts Labeling requires the following:

The Serving Facts Labeling requirement also recommends including on the label the list of ingredients, a freshness date, and a reference to a website with the information or a QR code on the label or secondary packaging. Your labeling software should have capabilities of combining graphics, text, and UPC barcodes, as well as features that allow for multiple database connections and variable data to ensure what you need printed is being done so correctly.

Incorrect packages or labels that fail to identify allergens are the leading cause of food recalls by the FDA and the US Department of Agriculture. For individuals with severe allergies, mislabeled food products can be deadly. That’s why preventing these mistakes and avoiding cross contamination with allergens is crucial.

The best label software for the food and beverage industry for staying compliant with food labeling regulations and keeping consumers safe is a solution that has multiple functionalities that can help you do so. You should be able to keep records of changes, comments, revisions, and print history for every label to not only prevent label-related recalls from happening, but also to quickly administer a recall in the unfortunate event a labeling error does occur. You should have the ability to establish user permissions throughout your labeling process to control access and ensure that only compliant and approved labels enter production. You should also have the ability to connect to multiple databases and leverage those connections to automatically populate and highlight allergens with listed in the ingredients.

The United States Food Allergen Labeling and Consumer Protection Act (FALCPA) requires the label of a food that contains any of the major food allergens listed below to declare its presence.

Major food allergens:

The Food Information for Consumers (FIC) regulation aims to protect consumers’ health by providing clearer and more readable labels. It pertains to food items sold in Europe, including imported food and food sold online.

For this regulation, your software should have capabilities to track origin for specific meat products, should be able to highlight allergens, and be able to incorporate mandatory nutrition information.

The European Union FIC requires these 14 common allergens to be stylistically highlighted on product packaging:

The Food Safety Modernization Act (FSMA) shifts the focus from responding to food contamination to preventing food contamination, which means preventing labeling errors in the food and beverage industry more important than ever.

When choosing the appropriate labeling software that helps your food and beverage company comply with FSMA, you should look for one that has data validation capabilities to prevent labeling errors from happening. Your software should have tools to improve labeling accuracy, avoiding the potential risk of recalls. This looks like automating steps in your process and integrating systems that allow for full visibility from field to fork - from the business' hands to the consumers table. It should also include an implementation of a label approval process, ensuring that only accurate labels are entering production. Having the capabilities to prevent labeling-related recalls, your barcode labeling software should have traceability and full visibility throughout your supply chain. If in the unfortunate instance that an item is recalled, your software should have the ability to trace it back to the source.

LABEL ARCHIVE is TEKLYNX label security and traceability software. If an item is recalled, LABEL ARCHIVE can help trace the affected labels and determine the source of the labeling error, eliminating waste and time spent. It also has user privileges and controls, giving your system a series of checks and balances to avoid these mistakes in the first place.

Interested to learn more? Check out our Navigating Food Labeling Requirements infographic. Or for a detailed breakdown of staying compliant in the food and beverage industry check out our Food Labeling White Paper.

Sartori has produced artisan and premium cheese for over seven decades. Multiple custom labels are required for their products, and their product line varies in size, type, and weight. They also required a wide variety of label types, such as pallet tags to track inventory quantity, various customer facing labels, and specific individual labels for both internal and external use. This variety results in a complex labeling process that Sartori sought to streamline.

Sartori faced labeling challenges that are common to many food and beverage manufacturers. Their label printing interface permitted users to modify label designs and content outside of a tracked process, manual data entry was time consuming and error-prone, and individual workstations were difficult to troubleshoot, resulting in an increase in IT expense.

After researching a few solutions, Sartori eventually decided on TEKLYNX CENTRAL, which had a simple web interface that was intuitive enough for team members to learn quickly, while also helping Sartori lock down label designs and apply user restrictions based on job roles. TEKLYNX CENTRAL’s web-based access also eliminated the need for individual workstation installations, which dramatically cut costs and administrative overhead.

The results after implementation speak for themselves. Print users were no longer able to modify label designs from their workstations, resulting in a significant decrease in errors. Full integration with Sartori’s ERP system ensured that all information provided on each label was accurate, and by using scan and print functionality, manual data entry was a thing of the past. TEKLYNX CENTRAL also helped Sartori develop formal labeling processes that are easy to enforce. Each workstation restricts the available labels to only those appropriate for their assigned task. This lets team members locate the correct template right away, as opposed to scrolling to locate the correct one among hundreds of options. Because of the implementation of TEKLYNX CENTRAL, the label printing process runs much more smoothly and error free.

Read the full Sartori case study.

Need some help getting started on finding the best label software for your food and beverage company?

Nick Recht is the Sales Manager for the Americas region at TEKLYNX RFID and barcode label solution provider. He leverages his passion for using technology to add value to businesses and his 15 years of AIDC experience to help organizations of all sizes barcode better. When he is not working, he is driving one of his daughters to a practice of some sort or doing a project around the house.

Without change there’s often no room for innovation or improvement.

READ MORE

You wouldn’t wait years to go to the doctor for a check–up.

READ MORE

Color labeling is not a new phenomenon. Manufacturers have long understood the value of incorporating color onto their labels. From branding and marketing to product identification, the opportunities color can provide are limitless.

READ MOREthe LABELVIEW is the greatest program for labeling that I've ever seen. Who is Bartender and others. My business is too small to get that program. This is a dream. Give me one licence please! Please.

ReplyWe agree that LABELVIEW is great! Give us a call and we can help you purchase the license you need. You can reach us at 414-837-4800 between the hours of 8am and 5pm CT.

ReplyIn an industry where accuracy, consistency, and compliance are paramount, having the right label software can be a game-changer. From ingredient listings to allergen warnings and nutrition facts, the intricacies of food labeling demand precision.

Reply© Copyright 2025 TEKLYNX CORPORATION SAS. Alle rechten voorbehouden.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.