Selecteer uw locatie en taal voor de beste website-ervaring

Barcodes are the foundation for many industries and one of the most crucial parts of business operations, yet often overlooked. For operations to remain efficient and error-free, barcodes must be correct on every product or package. An error as small as placing a number in the wrong position or violating quiet zones creates issues throughout the supply chain. And no one wants more supply chain problems to happen while already facing increased supply costs, labor shortages, and delays.

To keep your business and barcodes organized to prevent production downtime, chargebacks, and product recalls — avoid these eight common barcode mistakes and use compliant barcode label design software with over 100 barcode symbologies, built-in barcode wizards, database connections, and so much more.

Let’s start with the most common barcode mistakes we see and how our products and people at TEKLYNX can help you prevent barcode mistakes from happening.

Choosing the barcode symbology is one of the first and most important steps in creating a barcode. It’s an easy mistake to choose the wrong symbology but can it be avoided. Industries and regulations have different specifications to choose from based on the distributor or company their shipments are going to. Big distributors like Amazon and Walmart have specific requirements for what their barcodes can be and how to encode the data. TEKLYNX barcode label design software has over 100 symbologies to choose from, so whichever type of barcode your distributor may require we will have.

Each barcode symbology has a defined size that needs to be followed. If barcode sizes are edited incorrectly, they may become illegible, causing issues with both scanner readability and printing accuracy. This is also referred to as below minimum magnification. For example, UPC barcodes must only contain 12 digits and be 100% magnification factor (be able to be read by a scanner) and still fit on the package or product.

CODESOFT barcode label design software helps you with creating barcode dimensions. You can auto size the barcode chosen to fit a specified width, then when adjusting the width dots, the barcode x-dimension will change.

To avoid making your barcode too small, follow industry standards and sizes for each barcode type. You can read more about specific barcode standards on GS1.

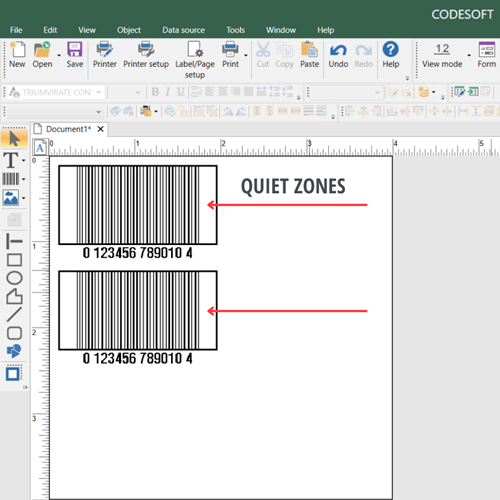

Violated quiet zones are another common barcode mistake. Quiet zones are the blank space around the barcode, also called the margins. This area should be kept clear of design elements such as logos, images, and text. Scanners read like humans left to right, so if there are any design elements or text on the end of the barcodes it may interfere with the scan, and result in incorrect data. The standard space on each side should be ten times the dimension of the narrowest element but can be bigger to make wider margins.

If you respect the standard space on each side of the barcode, you can avoid violating quiet zones. ITF 14 barcodes are a type of 1D barcode that help track items throughout supply chains, and when selected in CODESOFT, you can see the quiet zones on each side. This makes it easy to keep the standard space on each side so if you ever need to have multiple barcodes on one sheet, they all will be readable and scannable.

Barcodes usually contain black or blue lines and are placed on a white or transparent background. However, colored barcodes can also be used as long as they are readable. If you do ever want to change the color of the bars, be sure to choose the right color contrasts. Don’t choose a dark color if the barcode is on a dark background, and don’t choose a light color if your barcode is on a light or reflective material. Avoid using red for your barcode color since most scanners scan with a red light, which will make the barcode unscannable. If the colors clash, the barcode scanner will not be able to differentiate the background and the barcode making it unreadable.

Another common barcode mistake is encoding incorrect data or misplacing numbers in the barcode. Entering the wrong data can cause major headaches and leads to labels that don’t scan. The number one cause is human-error due to manual data entry.

Database connections enable label designs to pull variable data in from an existing business database or spreadsheet like Excel or Google Sheets. Instead of maintaining hundreds of separate label files, you can create a handful of label templates that use database connections to print variable data. Not only do database connections help print variable data but it pulls data directly from your templates in Excel, ensuring there will be few mistakes made because manual data entry isn’t happening. Use variable data to pull in dates, addresses, batch numbers, and more to reduce manual errors. Label designers in CODESOFT can also use counters for serial numbers, or the PortWatch feature, which allows you to collect data from a scale, such as the weight and prints it on the label without any manual data entry.

Similar to the mistake of encoding the wrong data, is adding the wrong number in the wrong position. Label designers oftentimes confuse the UPC prefix and GS1 prefix, placing them in the wrong position. Check digits and a compliant software provider like GS1 can help avoid barcode number misplacement. The last number on a UPC barcode is the check digit number, which is calculated using the other numbers on the barcode algorithm. When the check digit doesn’t match the numbers that were calculated, an error will be identified. TEKLYNX labeling software creates check digits to help designers ensure accuracy on their barcode labels.

Label misprints are a commonality in the barcode labeling industry. A warehouse floor worker may come and want to edit a label, but they might not know the regulation standards for the specific industry or how to enter the right data.

To stop this from happening, you only want your designated label designers to edit labels, not other employees on the floor who never touch the barcode software. With different label design or print roles, users won’t mistakenly edit a label they aren’t supposed to or print incorrect labels for the wrong products, which will reduce errors and help quality control issues.

CODESOFT includes features such as FormEditor and FormDesigner to help determine label design roles, separating design users from print users by organizing print time data entry and controls. User Manager is another feature in CODESOFT that helps establish user permissions for extra security, so only specific employees can open, edit, print, or save labels.

LABEL ARCHIVE label security and traceability software can establish user roles and permissions to control access to label files, enable a barcode verification process with TSC Printronix Auto ID ODV 2D, quickly help with reprints, and has a full version history where users can see who did what and when for every single label. When using these features, misprints should decrease, and quality control will increase.

Printer drivers are a critical component to enable a smooth label printing process. When users have low print quality or are not using native printer drivers, barcodes can become unreadable, and may print blurry. Printer drivers act as the bridge between barcode label software and the printer hardware, translating commands from the computer into a language the printer can understand. When this happens, your computer can print without knowing specific details of the hardware and software, so using a more reliable driver is important.

A windows printer driver is generic and is often used because it comes with your computer’s operating system. But they are not optimized for specific printers and will have limited functionality, and inconsistent and slow printing.

TEKLYNX embedded native printer drivers are specifically designed for printer models and provide the best performance. Using native printer drivers instead of Windows printer drivers gives you an advantage to fast printing, What You See Is What You Get (WYSIWYG) printing, robust connectivity, and more customization.

TEKLYNX has over 4,000 native printer drivers to choose from, including some of the most popular label printer models such as Brother, Zebra, Epson, Canon, BIXOLON, and many more. Using native printer drivers will provide the best overall quality for your barcode labeling needs.

We covered the top barcode mistakes due to design and printing, but the material of the barcode is just as important. Barcode damage happens often due to wear and tear through warehouses and shipping, and environmental conditions like exposure to sunlight, moisture/rain, and extreme temperatures. It’s common to use the wrong label media, so for your barcode to work properly and stay readable, your label stock must support any condition.

It’s crucial for label stock to be able to make it through durable situations. Common materials that can make it through wear and tear are non-paper, synthetic materials like polypropylene, polyester, or polyethylene, which are weather and scratch resistant. Read Smith-Corona's blog on durable label standards and requirements to find out how you can prevent wear and tear damage to your barcodes.

Barcodes might not seem very important in the grand scheme of things, but they truly are the foundation of many successful industries. When made incorrectly, barcodes can disrupt supply chain operations, cause chargebacks, initiate product recalls and quality control issues, create inventory disorganization, and so much more.

Creating and printing accurate barcode labels is essential, and you can prevent labeling errors from happening by avoiding these eight common barcode mistakes. Choose a software provider like TEKLYNX to stop mistakes from happening in your labeling process.

Download a free 30-day trial of CODESOFT barcode label design software to test out features like barcode generator wizards, database connections, user roles, variable data, and more, so you can barcode better.

Request a free demo of LABEL ARCHIVE to help with misprints, barcode verification, and label traceability.

Download free trial of CODESOFT

Request Free Demo of LABEL ARCHIVE

Nicole Lepkowski is the Customer Support Manager at TEKLYNX, where she actively coaches her team to ensure each customer's needs are met quickly and carefully. With over nine years of experience working with TEKLYNX software users, Nicole is dedicated to raising the bar in customer support and helping companies throughout the supply chain barcode better. Outside of her role at TEKLYNX, Nicole enjoys traveling and spending time with her family.

Barcodes are not just simple lines and numbers; they are powerful tools that facilitate seamless inventory management, enhance supply chain operations, and enable businesses to operate with remarkable efficiency. In this blog post, we will delve into the technicality behind barcodes, explore different types of barcodes, explain how barcodes work, discuss their diverse applications, and highlight why they are indispensable to the supply chain and businesses.

When you need to print a label, how long does it take to find the correct file, populate the correct data, and start the print job? If you’re not leveraging the power of variable data on smart label templates, it could take several minutes just to find the right label file!

READ MORE

Whether you're managing a small warehouse or a large-scale distribution center, implementing a labeling solution can streamline processes, improve accuracy, and enhance overall productivity. In this blog post, we’ll dig into the importance of having a streamlined warehouse labeling process in place and the key features of a successful warehouse labeling system.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. Alle rechten voorbehouden.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.