Please select your location & language for the best website experience

Color labeling is not a new phenomenon. Manufacturers have long understood the value of incorporating color onto their labels. From branding and marketing to product identification, the opportunities color can provide are limitless. On-demand color label printing provides a modern, flexible solution to address these challenges, giving businesses the ability to print high-quality, customized labels whenever and wherever they’re needed.

Learn more about on-demand color labeling

This blog explores the benefits of on-demand color labeling, the technology behind it, and how it drives operational efficiency while reducing costs.

On-demand color labeling refers to the ability to print full-color labels instantly, using inkjet printers, allowing businesses to create custom labels with artwork, barcodes, variable data, and vibrant graphics as needed. On-demand color labeling enhances branding, compliance, and operational efficiency.

Color can be essential in your labeling, offering benefits beyond aesthetics by enhancing communication and improving safety.

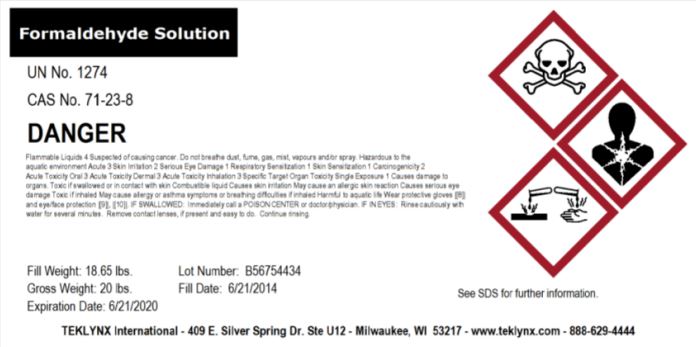

Color labels play a critical role in highlighting bold safety warnings and drawing attention to key information. The growing focus on industry standards and regulations requiring color, such as the Global Harmonized System of Classification and Labeling of Chemicals (GHS), cannabis labeling, and the US Food Allergen Labeling and Consumer Protection Act (FALCPA), has made color labeling increasingly important for manufacturers. For example, GHS mandates colored pictograms for hazardous materials to help reduce workplace injuries and illnesses.

Red diamonds on chemical labels serve as danger signs, warning people to use caution when handling the product due to its hazardous nature.

Beyond compliance, color coding improves internal processes and customer satisfaction. It helps differentiate products like models or part sizes, streamlines material handling, and enhances retail appeal with vibrant designs. By using color systems and reducing excessive text, manufacturers can boost traceability, safety, and efficiency.

With on-demand color labeling, businesses gain a powerful tool to cut costs, increase efficiency, and improve the accuracy and quality of their labeling processes.

Incorporating color into label designs can add complexity, making it essential to evaluate your business needs before selecting the right software, hardware, and materials to support your ideal labeling process.

First you must understand your production environment, warehousing setup, and labeling requirements. For example, a food manufacturer might need templates to quickly update ingredient labels with vibrant colors for allergen warnings, while a shipping company could require color-coded labels for easier sorting across warehouses. Then you must choose label design software; look for solutions that offer scalable options to meet your current needs and adapt as requirements grow. You should be able to select software with the functionality you need and the ability to easily upgrade to a more advanced solution as your needs change. For example, as your labeling grows more complex with an expanded product offering, you may need an enterprise label management solution to enhance automation, ensure version control, integrate with your business systems, and access advanced label management options.

When selecting a label printer, prioritize printers that balance quality and speed, ensuring they meet your label material and durability needs. You must also consider your requirements for label stock to ensure that the printer you choose will be able to print on that material using an ink type that will withstand the environment. For instance, pigment ink can create a durable image that can stand up to alcohol, acetone and other chemicals. Additionally, consider features that ensure compatibility with your label design software and include regular updates for printer drivers.

Epson’s ColorWorks label printers work seamlessly with TEKLYNX native printer drivers, delivering true WYSIWYG (What You See Is What You Get) results.

Start on-demand color labeling with TEKLYNX and take your label printing to the next level. With on-demand color labeling, you can design smart label templates that include variable data and images, allowing you to print exactly what you need when you need it. Eliminate the risks of print misalignment and the waste associated with pre-printed stock by bringing labeling in-house. You can reduce label stock inventory, minimize waste, and lower total label costs.

Experience reliable and efficient on-demand color labeling with TEKLYNX. Get in touch with a labeling expert to learn how you can benefit from on-demand color labeling.

Nick Recht is the Sales Manager for the Americas region at TEKLYNX RFID and barcode label solution provider. He leverages his passion for using technology to add value to businesses and his 15 years of AIDC experience to help organizations of all sizes barcode better. When he is not working, he is driving one of his daughters to a practice of some sort or doing a project around the house.

A constant theme in today's manufacturing world is the need for automation.

READ MORE

Everyone wants to do better. Whether it’s improving your health, career, or home, there’s always room to do things better. Well, what if I told you there’s a better way to design your barcode labels?

READ MORE

Within this blog, learn about the importance of remaining complaint with GHS labeling standards and how to create GHS compliant labels with TEKLYNX label design software.

READ MOREExcellent post. I am essentially satisfied with your amazing info. Glad to be one of several visitants on this amazing site.

Reply© Copyright 2025 TEKLYNX CORPORATION SAS. All Rights Reserved.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.