Please select your location & language for the best website experience

Like most logistics operations, yours might point to “receiving” as the main starting point in your operation. Either because it’s a process that often begins earlier in the day with the overnight arrival of trucks delivering products from all parts of the country, or simply because it’s the point in which materials enter your facility thus setting the stage for all other processes.

Either way, optimizing your dock-to-stock process is critical if you want to survive in the age of Amazon – when you’re competing against robots, drones, and same-day shipping. A recent report from American Productivity and Quality Center found that top performers in dock-to-stock get the task done in just under four hours, while the bottom performers took 48 hours.

That’s a difference of 44 hours, translating to lost time and revenue for the company. If you can save time by increasing efficiencies, employees will be freed up to focus on other tasks that will drive ROI. But where do you start? How do you improve your dock-to-stock results? Here are three ways you can optimize dock-to-stock processes.

A warehouse employee takes countless unnecessary steps throughout the day. While it may sound like great exercise, it’s less ideal for warehouse efficiency. It’s estimated that each step a warehouse associate takes can cost the company 3 to 4 cents. While 3 to 4 cents per step may not seem like much, if each worker is taking tens of thousands of steps per day, the cost adds up.

During a recent warehouse tour, one supervisor told me his employees walk seven to nine miles every day. If they are walking that many steps a day, something is very wrong, and it’s likely an inefficient layout or process that is causing all of that motion.

One area where motion is a major problem is in the typical receiving process where operators pull paperwork from a load, walk to a PC, look up the PO, walk back and verify counts, walk back to the PC, print labels, and then walk back to apply the labels. There can be as much as 50% waste in this process. To get to world-class dock-to-stock times, it’s about minimizing non-value-added activity; walking is low hanging fruit that can removed by leveraging carts and mobile solutions to allow for label printing at the point of activity.

By eliminating paperwork, leveraging print automation, and relying on mobile technology, companies can effectively reduce dock-to-stock cycle time, reduce labor by as much as $10,000 per worker, eliminate improperly labeled products and minimize inaccurate inventories.

RF scanning is vital in the receiving process because wireless technology will limit the number of steps associates are taking to various areas throughout the warehouse and reduces inaccuracies in reporting. It frees them up for other tasks pertinent to workflow. Rolling out RF scanning doesn’t take long, and the added sophistication will go a long way in limiting time and paper waste.

There are a lot of companies that want to go paperless, but they still lack an automated system for inventory management. Once those firms realize that they can effectively reduce the amount of time it takes to unload a trailer and put it away to stock, they begin to see the true advantages of making that happen on a regular basis. That, in turn, pushes them to explore more mobile options scanning and printing.

To improve speed while still maintaining accuracy, humanitarian aid organization Direct Relief recently moved to paperless processing in its warehouse.

“In the first month, we had an increase of 40 percent of the number of batches that we received,” said Thomas Tighe, president and CEO, Direct Relief. “We did them more accurately and in 20 percent less time. We’ve also been able to cut the time it takes to pack and ship by almost 70 percent due to the increased efficiency.”

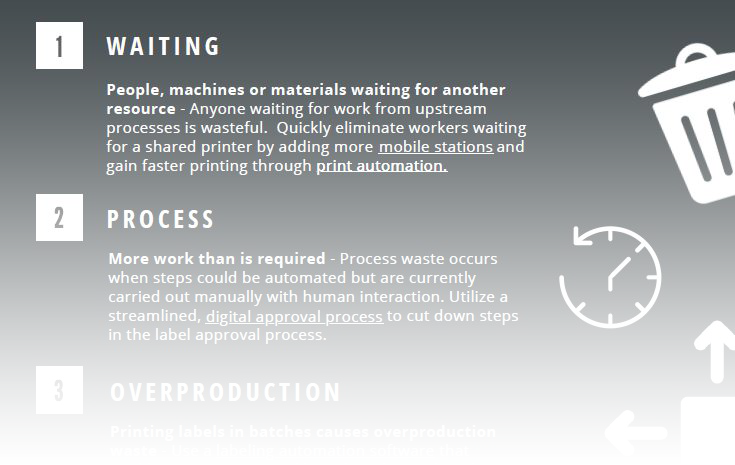

Check out the new infographic from TEKLYNX, Newcastle, and Zebra on 7 Ways to Eliminate Waste in Your Labeling Process.

When it comes to world-class receiving and put away, one of the general principles is to try to minimize the number of handling steps throughout the process.

Warehouse and logistics professionals have a tough task. The industry is changing, and customer demand for speed has never been greater. By reducing movement, paperwork, and touches, you will improve the flow of the warehouse and reach true dock-to-stock optimization.

Check out these resources from TEKLYNX, Newcastle, and Zebra:

Check out these resources from TEKLYNX, Newcastle, and Zebra:

To learn more how you can create efficiencies through the use of mobile carts in your logistics visit www.newcastlesys.com.

Kevin Ledversis serves as Sales Director at Newcastle Systems and helps customers identify where and how process improvements can be made in warehouse operations using barcode technology. Mr. Ledversis has over 25 years of experience within the Automatic Identification and Data Capture (AIDC) industry. Prior to joining Newcastle Systems, he worked in sales for Weber Labeling Solutions, Intermec and Printronix where he developed solutions for complex labeling applications in a variety of verticals such as distribution, manufacturing, healthcare and retail. Mr. Ledversis earned his MBA degree from University of Hartford and a bachelor’s degree from Bryant University.

He received his Lean Bronze training from the Greater Boston Manufacturing Partnership and his Lean Six Sigma Green Belt from Leancor and sits on the Regional Board for the Association for Manufacturing Excellence.

As 2020 comes to a close, it’s time to look forward to 2021. Let’s take a look at five major manufacturing trends that, while undeniably accelerated by the events of 2020, will hold true into 2021 and beyond. For each trend, we’ll dive into ways labeling will evolve in 2021 to support manufacturing.

READ MORE

Barcode label printing software offers an array of benefits to businesses of all sizes. So, how should a small business owner choose the best barcode label printing software? Consider your label printing needs today, but don't forget to look to the future. Follow these tips.

READ MORE

Manufacturers today are part of a global supply chain, sometimes specializing in one product or process. In a vast supply chain made up of contract manufacturers, suppliers, warehousing providers, and distribution specialists, labeling is the common language that allows every link in the supply chain to work together.

READ MOREFantastic insights on optimizing dock-to-stock processes The blog provides valuable strategies for improving efficiency and streamlining operations. Well done!

Reply© Copyright 2025 TEKLYNX CORPORATION SAS. All Rights Reserved.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.