Pro co nejlepší zkušenost s těmito webovými stránkami prosím zvolte polohu a jazyk

Pro co nejlepší zkušenost s těmito webovými stránkami prosím zvolte polohu a jazyk

Total Cost of Ownership (TCO) is a helpful concept for making business purchase decisions. TCO includes the upfront cost, related costs, and estimated ongoing related costs throughout the useful life of the purchase.

TCO is often compared to an iceberg because the obvious costs, like the tip of the iceberg, represent only a small portion of the total. Many costs are hidden beneath the surface, just like the true size of an iceberg is hidden underwater. A detailed TCO analysis can help reveal the full "iceberg," ensuring you're prepared for all costs—not just the obvious ones. Analyzing the TCO across multiple vendors creates an objective comparison to guide your purchasing decision.

When choosing a label management solution for your business, consider the TCO to help your company plan expenses and estimate return on investment (ROI).

In this blog, we’ll explore how to find the TCO for label management solutions, including 30+ questions to ask potential vendors and pitfalls to avoid.

TCO is the total cost of a solution over its lifespan. For label management solutions, this includes the software purchase, implementation costs, ongoing support costs, and ongoing maintenance costs. Much of the TCO is set by the software vendor, such as the software price and hourly rate for related services. Some of the TCO can be influenced by the buyer, including labor costs, infrastructure costs, and training costs.

When comparing two or more label management vendors, TCO is a great tool to make an objective “apples to apples” comparison. Often, different vendors offer different licensing options, support contracts, and policies. Vendor A may offer a lower cost for ongoing support but subject its customers to price increases. Vendor B may offer a higher cost for ongoing support but allow customers to lock in their price. The better option depends on how long you plan to use the software, the average price increase of Vendor A, and the quality of support offered by both vendors. There are many factors to consider!

TCO is a valuable tool to estimate future costs. It forces you to consider questions that aren’t always top of mind when researching label management software solutions: How will new staff be trained on this solution? How many user or printer licenses will you need in 1 year? 3 years? 5 years? What happens when your business system gets upgraded? What happens when a new Windows operating system is released? TCO helps you answer these questions before they surprise you.

Keep in mind that TCO is an estimate based on the information you have now. You can’t predict the future, but you can make a good guess. Don’t get lost in the tiny details but aim for a realistic general estimate.

Now, let’s explore the costs that may be included in a label management software TCO calculation. Each section includes multiple questions to ask potential software vendors.

Use these links to jump ahead to:

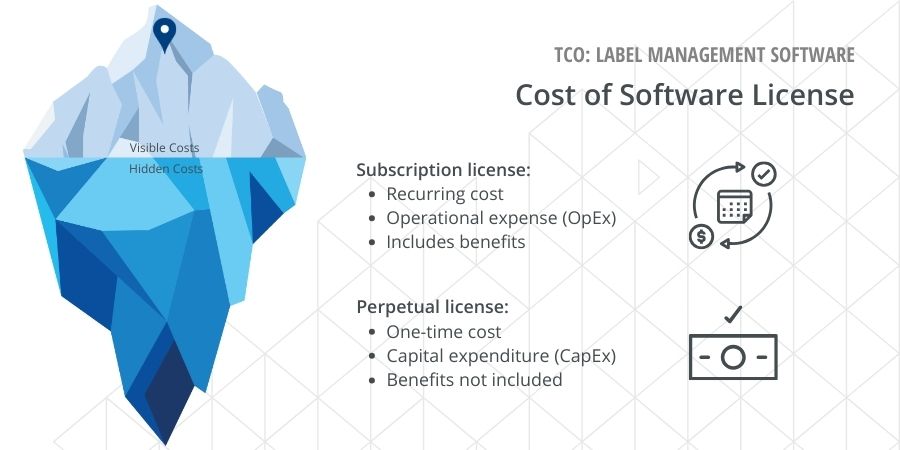

To use any label management software, you have to license it from the developer. Most software companies prioritize subscription licensing, but some still offer perpetual licensing. Let’s discuss the pros, cons, and accounting impacts of each model.

A subscription license requires a recurring payment to maintain access to the software license. It can be thought of as “renting” the license. When you stop paying, you lose access to the license.

Subscription licenses often include valuable benefits: technical support, free version upgrades, and training, for example. The ongoing cost supports the ability of the developer to offer technical support, provide bug fixes, and improve the software over time.

Since subscription licenses are an ongoing cost, they are considered an operational expense (OpEx) for accounting.

A perpetual license is bought with a one-time payment. The license that was purchased is yours to keep in perpetuity.

Perpetual licenses typically do not include version upgrades or technical support. In a few years, the license version will be outdated. To maintain a secure and modern technology environment, you will have to buy a new license on the latest version.

Software companies often offer (or require) Software Maintenance Agreements (SMAs) or support contracts alongside a perpetual license purchase. This ongoing cost includes access to technical support, version upgrades, and training.

Since perpetual licenses are a one-time investment, they are considered a capital expenditure (CapEx) for accounting.

Apart from the licensing model, it’s critical to understand what the license price is based on. Label management software is often priced based on a combination of users, devices, and usage.

As you calculate the TCO of a potential label management solution, make sure to incorporate your company’s growth goals. How much will the license cost grow as you add users and devices and increase usage?

Licensing questions to ask a potential vendor:

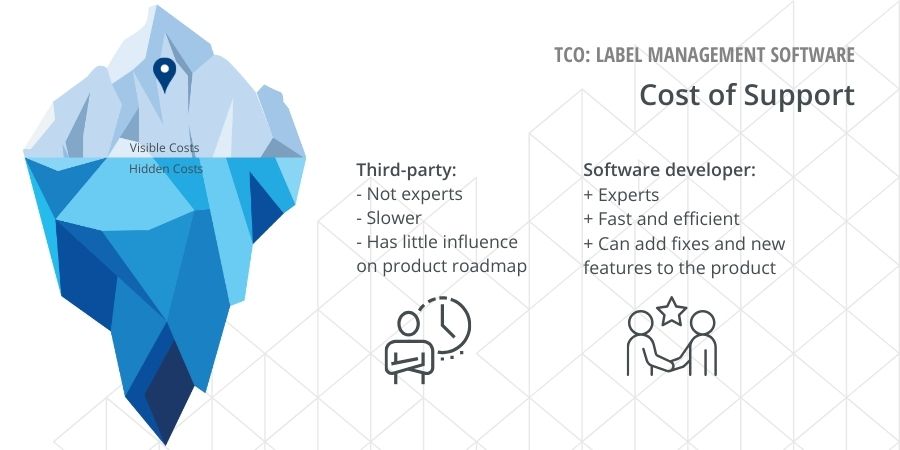

Support will likely be the second largest investment when purchasing a label management solution. Every software solution needs support. Support typically includes help using the software, troubleshooting, answering questions about how it works, and providing solutions to issues that may arise.

The best company to support your label management software is the one that makes it. Getting first-party support from the software developer means they are deeply familiar with the software. Your issues will be solved quickly, and your support representative may recommend a better way to use the software that prevents recurring issues. The software developer maintains a log of known issues and enhancement requests, meaning your discussion with first-party support can directly result in a software enhancement!

It may be possible to purchase a support contract from a third party. A third party may have some level of expertise with the software, but they likely work with many software packages and have a shallower understanding of all of them. It may take much longer to resolve issues. Finally, your third-party support representative won’t have a direct influence on the future development of the software. Be wary of selecting third-party support for a business-critical solution like label management.

No matter who you choose to support your software, it’s important to know the support policies and availability. If your company requires a high-availability environment, you may need 24/7 support on your label management software. If your company is in a highly regulated industry, such as life sciences, technology environment validation may be required. This means you must carefully evaluate any changes and may skip version upgrades. These companies need to know whether old versions will continue to be supported into the future.

Consider these questions when calculating the cost of support for your label management software TCO.

Support questions to ask a potential vendor:

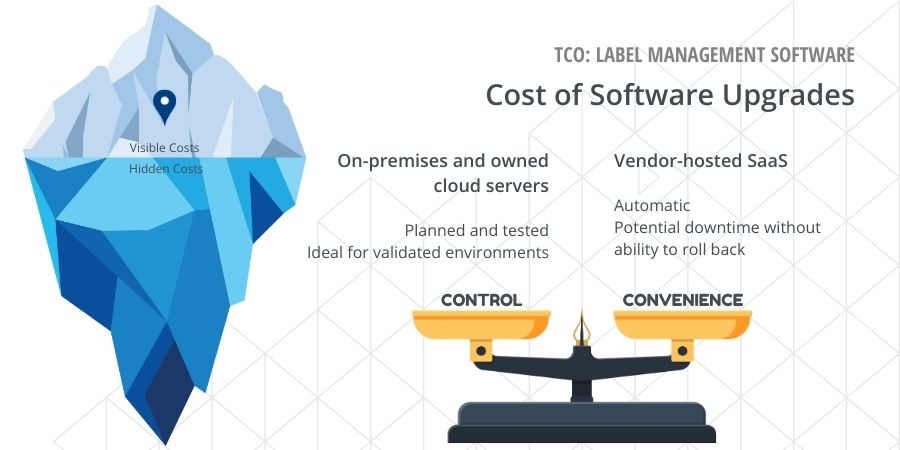

Software upgrades are necessary for maintaining the security and workability of your label management solution. Upgrades ensure the software continues to work with modern technology, including the latest Windows operating system, the newest server technology, and updated programming tools. The latest version of your label management software also includes improvements to usability and new features.

Revisit the section above on software license costs – does your license include software upgrades? Subscription licenses typically include software upgrades. Perpetual licenses typically do not include software upgrades, but an SMA or support contract can be added to provide access to upgrades.

The process of upgrading your label management software depends greatly on how it is hosted.

When your software is installed on an on-premises or owned cloud server, you are in complete control over when an upgrade is performed. Upgrades are usually less frequent and may cause a short and predictable downtime.

SaaS software is entirely controlled by the vendor. It is often upgraded on an ongoing basis, with small updates being rolled out weekly or daily. While this takes the burden off your internal IT team, it also takes control out of your hands. If an upgrade breaks a process or integration, you may not have the ability to roll it back quickly. Worst case, you could end up with large unplanned downtime.

Upgrade questions to ask your vendor:

Infrastructure costs include the hardware required to run the label management software. While cloud-based software is becoming more mainstream, many organizations still maintain robust on-premises technology environments.

When you host your label management software on-premises, infrastructure costs include the cost of the server. Costs may depend on server specifications and data storage requirements.

Incorporating these costs into your TCO for label management software requires nuance. An on-premises server is likely used for multiple purposes, not just label management. You may decide to allocate a portion of infrastructure costs to your label management software TCO based on the percentage consumed by the solution.

There are two options for hosting your label management software in the cloud, each with their own costs and benefits.

Self-hosted: Many companies use their own cloud server on services such as Azure or AWS and install the label management software there. This approach allows IT teams to maintain control over the applications while gaining the benefits of cloud computing. With a self-hosted approach, the cost of cloud servers is well known and may be allocated to your TCO in a similar way to on-premises servers.

Vendor-hosted: The second option is for the software vendor to host the label management software in the cloud, removing the responsibility from the customer. SaaS solutions are always vendor-hosted. With this approach, the infrastructure costs are often hidden and rolled into the licensing fee.

Infrastructure questions to ask a potential vendor:

Label management software is built to remove manual touchpoints from your label printing process. For this reason, labor costs should be a small portion of your label management TCO.

Automated data entry means that users don’t manually enter data onto label templates. Not only does this save time, but it prevents errors that lead to future wasted time.

Automated label printing means that label print jobs are initiated programmatically by business actions. Print jobs can be driven by events in your ERP system, adding a record to a database, or via REST API.

Automated label approval processes mean that creating or editing label templates follow a defined electronic process. This eliminates confusion for the staff designing, approving, and printing labels.

A central repository for label files means users don’t spend time searching for a label file, only to open the wrong one. It also enables version control, making it quick to roll back to a previous version of a label.

The labor costs section of your TCO may become negative due to the reduction of manual steps in the label printing process. It’s still a valuable tool to compare label management software and determine which solution offers better labor cost savings.

Labor questions to ask a potential vendor:

Any new software solution requires training. Your label management software TCO should include the hours it will take to train software administrators, label designers, label approvals, and, if necessary, print users. Find out if your vendor includes free training or charges an additional cost.

Since label management software reduces the need for staff to interact with the software, ongoing training costs decrease dramatically.

Without label management software, staff have to interact with a label printing application. They must be trained on how to locate the correct label file, populate the correct data, print to the correct printer, and what to do in case of a mistake. For a large manufacturer, this could be dozens or hundreds of staff. With staff turnover, training is never-ending.

With label management software, all these steps are automated by the system or driven by business logic. Sometimes staff still need to interact with a label printing interface, but it is greatly simplified to make training easy. The label printing interface can even be customized to match the business system for maximum usability.

Training questions to ask a potential vendor:

The power of label management software comes from its ability to integrate with other business systems. Labels must contain accurate data, and that data is typically housed in a business system. Integration allows the data to flow directly onto the label template.

There are two strategies for business system labeling integration with vastly different cost implications.

A deep integration between your business system and label management solution requires extensive programming which incurs costs. If your company uses a custom or less well-known business system, this work could fall onto your internal resources. If your company uses a widely used business system like SAP, Oracle, or Microsoft Dynamics, your software vendor may offer a connector. These connectors still require ongoing development, maintenance, and upgrades, resulting in greater cost to the customer.

When it comes to system integration, there is a persistent myth that deeper, more custom integration yields better results. When it comes to label management, this is simply not true.

The end goal of getting business data onto labels can be efficiently achieved by a low-code business system integration. Traditionally, this is done by exporting a “flat” file (.txt, .csv, or .xml file) from the business system to a watch folder. The label management software reads the file and prints the labels. It can also be achieved by adding a record to a watched database. A more modern method is to use REST API to send label print job data. REST API also allows you to send data back from your label management solution to your business system (i.e. label print job status).

Low-code integrations are almost never affected by system upgrades. Because the integration is universal, the label management software can simply continue printing labels with data from the updated system.

If you choose deep integration between your business system and labeling solution, be sure to account for ongoing development costs every year.

Integration questions to ask a potential vendor:

When searching for the ideal label management solution for your company, you should define a list of requirements. What are the “must have” features to meet your company’s label management needs? What would be “nice to have”?

Companies are often faced with two possible approaches: custom software and out-of-the-box software.

It can be tempting to invest in custom software to perfectly meet all your requirements. However, the TCO can be astronomical. Custom software requires the work of highly skilled (and highly paid) developers. The timeline to launch custom software is often long, delaying the opportunity to build ROI. After custom software is launched, it must be maintained and enhanced. Maintenance keeps the application secure, updated, and compatible with other systems. Enhancements meet the future needs of users, systems, and processes. Both maintenance and enhancements require more expensive development work. Not only is the TCO of custom software high, but it’s difficult to accurately predict.

Configurable out-of-the-box, also known as commercial off-the-shelf (COTS), label management software is a much more cost-effective solution. It represents a middle ground between expensive custom software and basic out-of-the-box software. COTS solutions come with an array of options and settings that can be used to create your ideal label management system.

COTS software developers are focused on providing solutions to real customer demands. Often, when users request a new feature in the software, it gets added as an option for all customers to use.

While COTS label management solutions may take longer to set up than basic out-of-the-box software, they offer huge savings on TCO compared to custom software.

When it comes to custom vs. COTS labeling solutions, the right choice is clear: COTS offers more bang for your buck.

Questions to ask a potential custom software vendor:

Questions to ask a potential COTS vendor:

After exploring this deep dive on label management TCO, you may be wondering which label management software provider offers the most value for the lowest TCO. Here are five ways TEKLYNX label management software, TEKLYNX CENTRAL, keeps TCO low for our customers.

TEKLYNX CENTRAL label management software licenses are based on four core elements: administrator licenses, design users, print users, and printers. Customers can increase these counts at any time or decrease at the time of renewal.

Hosting TEKLYNX CENTRAL on your company’s owned cloud server won’t cost anything extra. For TEKLYNX-hosted implementations, the hosting cost is transparently passed through to the customer.

Support for your TEKLYNX CENTRAL solution is purchased through a support contract, which can be renewed on 1-, 3-, or 5-year terms. Support contracts can include 24/7 access to support or be limited to business hours.

TEKLYNX publishes our support cycle policy on our website to provide consistent and predictable guidelines.

TEKLYNX Americas provides highly responsive and effective customer and technical support directly to our customers. We maintain an outstanding 95% customer satisfaction rate and gather countless positive customer testimonials.

Customer support policies vary by global region. Contact TEKLYNX in your region to learn more.

TEKLYNX CENTRAL label management software is purpose-built to reduce manual touchpoints within your labeling process. Every reduction in manual work results in a decrease in the cost of labor for label printing. Automation features include:

TEKLYNX CENTRAL is highly configurable to meet your label management requirements out-of-the-box. Many features can be turned on or off within the settings, providing a custom experience at an out-of-the-box price.

TEKLYNX has a habit of listening to our customers. We often add new features to our label management software based on customer requests, making useful enhancements available to all customers.

TEKLYNX CENTRAL uses universal, low-code integration methods to connect to business data. This eliminates the need for expensive custom development.

The three most common ways to integrate your business system with TEKLYNX CENTRAL include:

TEKLYNX label management solution, TEKLYNX CENTRAL, offers remarkably low TCO for the value it provides to a business. Find out how much TEKLYNX CENTRAL can save you by requesting a free consult for your company.

Request TEKLYNX CENTRAL Consult

Bill McCluskey is an Enterprise Executive at TEKLYNX who is passionate about listening to customers and prospects who need help solving problems beyond the capabilities of their current software or processes. He thrives on collaborating with customers and TEKLYNX' exceptional Engineers to deliver proven solutions that exceed expectations. Outside of work, Bill enjoys live music, spending time with friends and family, and supporting the Green Bay Packers, Milwaukee Bucks, and Brewers.

Connecting your labeling system with your current business systems, like an enterprise resource planning (ERP) system or warehouse management system (WMS), can boost your ROI without investing in a new system. By using what you already have and adding automated labeling, you can tap into your existing data to get a clearer view of operations.

READ MORE

You wouldn’t wait years to go to the doctor for a check–up.

READ MORE

At first glance, the custom option to almost anything sounds like the ideal solution. It's tailored to your needs exactly - what more could you ask for. If you're looking to save money and reduce unnecessary headaches, custom designed solutions might not be the right fit for you.

READ MORE© Copyright 2025 TEKLYNX CORPORATION SAS. Všechna práva vyhrazena.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.