Pro co nejlepší zkušenost s těmito webovými stránkami prosím zvolte polohu a jazyk

Pro co nejlepší zkušenost s těmito webovými stránkami prosím zvolte polohu a jazyk

Radio Frequency Identification, also known as RFID, is a form of technology that uses electromagnetic fields and signals to automatically identify and track specific items based on their tag or label. Active RFID tags consist of a chip, antenna, and housing and are powered by a battery. Passive RFID tags consist of the chip, antenna, and housing and don’t require a battery because they receive their power from the electromagnetism generated by a reading device. The connection between the tag and the reader is used to encode the tag with item-unique data, allowing for that item to be easily tracked and identified in the supply chain. This item-level visibility allows organizations to increase their operational efficiency.

Learn more about RFID label software

RFID is a rapidly growing technology that is becoming more common in business operations. According to a 2021 report by Allied Market Research, “the global RFID market size was valued at $10.41 billion in 2020 and is expected to hit $25.47 billion by 2030.” Businesses can use RFID to automatically capture information on packages or tags in order to track specific items. Encoding RFID tags helps companies access real-time data, reduce costs, and eliminate manual processes such as locating and scanning barcodes.

This blog will break down the benefits of RFID, how TEKLYNX software supports RFID technology, where RFID is used, and how to make an RFID label.

RFID technology has many business benefits including:

TEKLYNX software supports both RAIN RFID, often referred to as UHF Passive (Ultra High Frequency), GS1 EPC (Electronic Product Code), or ISO 18000-63 and HF/NFC High Frequency Near Field Communication. TEKLYNX label design software allows you to create UHF passive labels with RFID objects using text, images, and other barcodes.

Passive tags have no internal power source, so they can essentially last forever unless damaged. They are powered by electromagnetic energy transmitted from an RFID reader. The cost of RFID may cause some uncertainty for businesses. Chris Brown an RFID expert from TSC Printronix estimates that passive tags generally cost between 7 and 20 cents but can be as low as 5 cents when sourced in larger volumes. Since passive RFID has a lower price point, these tags become more economical for many industries.

TEKLYNX also supports on-demand smart RFID labels. Smart RFID labels combine RFID encodings with printed barcodes and text, all of which can be variable from label to label. The label can be printed as a barcode or as an RFID tag. Most companies utilize both barcodes and RFID to run a hybrid process. A hybrid process combines the features of passive RFID labels, or smart RFID labels, on top of standard barcode labels, creating one complete view of all your labels and traceability.

Passive RFID can be used for applications such as:

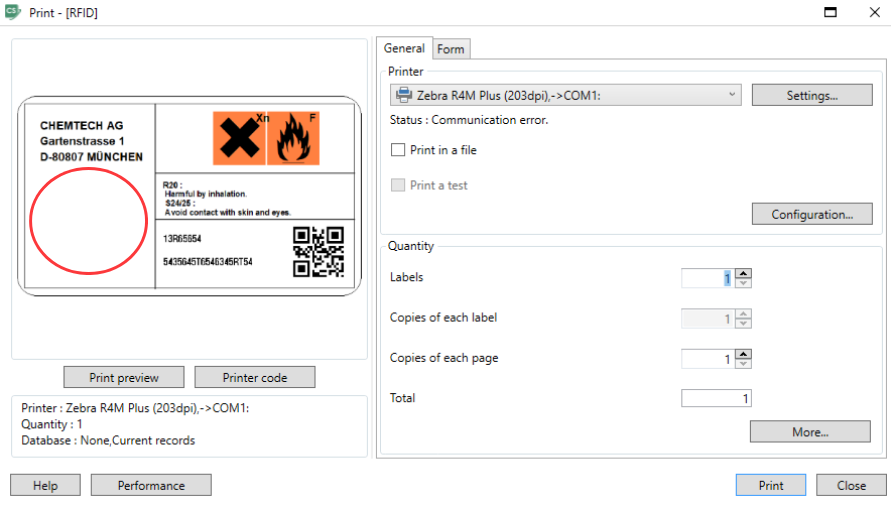

Barcode label design software is an important part of the puzzle in order to encode RFID on barcode labels, tags, or packages. But there is specific equipment you need to be able to print RFID labels and to use RFID technology in general. Hardware such as readers, scanners, and printers, as well as labeling supplies such as RFID label stock, are necessities to use RFID technology. Choose a technology partner who works with industry leaders in labeling hardware.

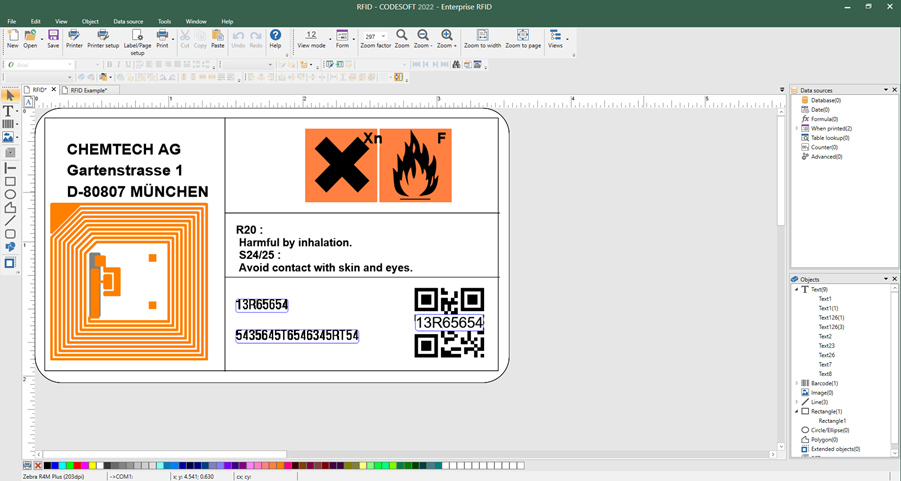

CODESOFT makes it easy to design and create RFID labels. When you are designing RFID labels, be sure to consider the standards applicable for your labels. If you use RAIN RFID, you will need to select a “numbering system” from either GS1 EPC or an ISO/IEC standard. If you are using HF-NFC, you will need to choose between ISO/IEC 15693 & ISO/IEC 14443.

For another quick and easy step-by-step explanation, watch this short video: How to Create an RFID label in CODESOFT. If you have any additional questions on barcode labeling, contact our customer support team that works around the clock to help you barcode better.

CODESOFT Enterprise RFID is an advanced barcode label design software from TEKLYNX. It can be used for all labeling needs, from simple text labels to barcode labels to RFID labels, as well as any combination. TEKLYNX enterprise label management solutions SENTINEL, LABEL ARCHIVE, and TEKLYNX CENTRAL, all leverage CODESOFT for label design, meaning the enterprise label management solutions all support RFID labels as well. Below are many of the supported tag types that are available in RFID-capable printers.

TEKLYNX also supports most formats, also known as identifiers for data encoding (numbering systems) on RFID tags, including:

RFID is becoming more common in retail, manufacturing, healthcare, and the cannabis industry. As RFID technology grows, more businesses are starting to incorporate RFID into their barcode labeling processes to increase security, meet regulatory compliance, and eliminate manual processes. Watch our free on-demand webinar: Incorporating RFID Into Your Labeling Process to learn more about RFID and how to integrate it into your business operations.

Improve supply chain visibility and your barcode labeling processes with RFID and TEKLYNX, and download a free 30-day trial of CODESOFT RFID label software to see how it can meet your business needs. If you don’t know where to begin, get in touch with a TEKLYNX labeling expert who can help guide you in the right direction.

Chris Brown an RFID expert from TSC Printronix contributed to this blog.

Travis Wayne is the Product Manager at TEKLYNX. Travis applies his 20+ years of IT and health sciences experience to empower businesses to streamline operations and barcode better by applying software and technology. He works to continually improve TEKLYNX strategic planning, product and project management principles, and cross-functional communications. When not working, he enjoys many outdoor activities with his wife and two children.

According to the Enterprisers Project, security must be a top priority for technology executives in 2022. Building a secure barcode labeling process is an important piece of a company’s security strategy that has a direct impact on the bottom line.

Mislabeling is one of the top causes of recalls in the United States, and labeling errors stem from gaps in labeling security. This blog will discuss ways to create a managed, controlled, and secure barcode labeling process leveraging better connections between people, software, and process.

READ MORE

When labor shortages happen, but consumers continue to want their products quickly, companies are forced to focus their resources on the most critical areas of their business. While labeling is absolutely a critical business function, it doesn’t need to use up valuable person-hours. When your company faces labor shortages, here are seven key ways to make labeling less manual so your staff can focus on other value-added activities.

READ MORE

Barcode symbologies differ by the type of data they hold and are encoded with. In this blog, we go over the categories of barcodes, the most common types of barcodes, and how to choose the best one for your labels.

READ MOREI work for Carpenter Technology. We manufacture specialty alloy stainless steel bars. We are seeking a way to track the location of these bar both inside and outside of the steel mill at our location in Tanner, Alabama, USA. I believe your software is exactly what we are seeking.

ReplyHi Matthew. That's great to hear if you fill out this form here we can set you up with a labeling expert to get you started. https://www.teklynx.com/request/get-in-touch

Reply© Copyright 2025 TEKLYNX CORPORATION SAS. Všechna práva vyhrazena.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.