Válassza ki tartózkodási helyét és nyelvét, hogy a legjobb felhasználói élményben legyen része

Válassza ki tartózkodási helyét és nyelvét, hogy a legjobb felhasználói élményben legyen része

There is a heavy emphasis on decreasing errors and maximizing your return on investment (ROI) in virtually every industry. Why would you not want to get the most bang for your buck? Integrating label printing systems with SAP is a guaranteed way to decrease labeling errors and maximize ROI while also speeding up your label printing process.

GET IN TOUCH WITH A LABELING EXPERT

Integrating labeling software with SAP helps organizations of all complexities run their businesses efficiently and cohesively. Companies seek integration and automation with SAP because of the long-term positive benefits they hold. Integrating SAP into your process reduces the need to manually enter critical data resulting in fewer mistakes made. Integrating labeling software with SAP from TEKLYNX is an easy way to make labeling changes fast, easy, error-free. Your existing SAP system holds all the necessary information needed to be printed, but when integrated with labeling becomes a more cost-effective and efficient process.

To ensure your time and your money is best spent, focus on light integrations between the software systems in your labeling environment. A deep integration sounds ideal at first, but when it gets to be more complex, upgrades can become a hassle, taking days or weeks to complete to ensure your updated labeling system is working correctly. This leaves the door open for software developers to keep sending you bills. Instead, focus on simple integrations so when an SAP label printing software is implemented into your technology environment, you’re avoiding complex system integration and constraints.

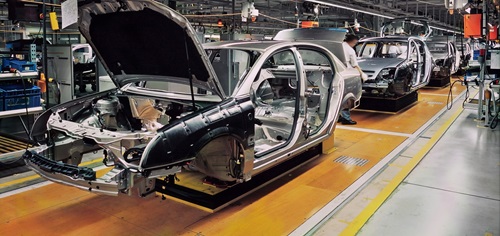

Nemak is a leading provider of lightweighting solutions for the global automotive industry, specifically in the development and manufacturing of aluminum components for powertrain and body structure applications. Their former labeling environment allowed all users to access label templates, had minimal security checks, and a lack of validation between roles. This combination, partnered with disparate systems across the labeling environment, made their labeling process difficult to manage and put the business at risk of costly errors and chargebacks.

Nemak is a leading provider of lightweighting solutions for the global automotive industry, specifically in the development and manufacturing of aluminum components for powertrain and body structure applications. Their former labeling environment allowed all users to access label templates, had minimal security checks, and a lack of validation between roles. This combination, partnered with disparate systems across the labeling environment, made their labeling process difficult to manage and put the business at risk of costly errors and chargebacks.

Nemak was already using TEKLYNX label design solution, LABEL MATRIX, with Zebra printers and their SAP ERP system. After business expansions leaving them with a mix of disparate systems, they were looking for a unified solution that allowed for a more efficient system to eliminate human interaction and enable compliant automotive label printing. They wanted to remain with TEKLYNX software, so decided on an enterprise level solution, TEKLYNX CENTRAL. Integrating TEKLYNX label printing software with SAP allowed Nemak to increase labeling accuracy by 98% while also instilling a secure label approval process. By standardizing and automating their systems, Nemak was better set up for success and future growth within the automotive industry.

Owens Corning is a global manufacturer of building materials and composites, with over 15,000 employees and 65 plants worldwide. Their former labeling environment limited ability to incorporate new technologies such as RFID or 2D barcodes into label templates and had a manual process that was time-consuming and error-prone.

The team at Owens Corning knew they wanted to integrate their label printing software with SAP to automate manual steps. They ultimately decided on SENTINEL, TEKLYNX’ print automation solution, and immediately saw a 75% reduction in development costs and time associated by printing barcode labels directly out of SAP. The appropriate label data was simply being exported from SAP in a flat file without excessive custom development. With their new SAP label printing software implemented, they were able to focus on the rollout of 20 plants and continue expanding SENTINEL’s reach as they add divisions and product lines throughout the company.

Read the Owens Corning case study.

bioMérieux is a multinational biotechnology company whose main goal is to improve public health around the world. With customers in more than 160 countries, bioMérieux provides in vitro diagnostic solutions to improve patient health and ensure consumer safety. Headquartered in France, bioMérieux’s labeling environment had a variety of barcode labeling software solutions in place making it increasingly difficult and inefficient to perform product updates and manage consistency. Being in a highly regulated field coupled with inconsistencies in labeling software produced manual errors throughout their entire process. They needed a solution that could eliminate those manual steps, input consistency with creating GS1 and Unique Device Identification (UDI) compliant labels, and integrate with their current business system, SAP ECC.

bioMérieux is a multinational biotechnology company whose main goal is to improve public health around the world. With customers in more than 160 countries, bioMérieux provides in vitro diagnostic solutions to improve patient health and ensure consumer safety. Headquartered in France, bioMérieux’s labeling environment had a variety of barcode labeling software solutions in place making it increasingly difficult and inefficient to perform product updates and manage consistency. Being in a highly regulated field coupled with inconsistencies in labeling software produced manual errors throughout their entire process. They needed a solution that could eliminate those manual steps, input consistency with creating GS1 and Unique Device Identification (UDI) compliant labels, and integrate with their current business system, SAP ECC.

By removing disparate labeling systems and implementing SAP label printing software with TEKLYNX CENTRAL, bioMérieux was finally able to consistently comply with GS1 standards and UDI regulations while gaining labeling accuracy and efficiency. They were able to experience exponential improvements in labeling accuracy while producing compliant labels 100% of the time. These integrations allowed them to meet current labeling objections while simultaneously preparing for future growth.

Read the bioMérieux case study.

Talk with a labeling expert at TEKLYNX to discuss how integrating label printing software with SAP can benefit your company.

Check out our recent TekTip video below about integrating CODESOFT with SAP HANA:

Travis Wayne is the Product Manager at TEKLYNX. Travis applies his 20+ years of IT and health sciences experience to empower businesses to streamline operations and barcode better by applying software and technology. He works to continually improve TEKLYNX strategic planning, product and project management principles, and cross-functional communications. When not working, he enjoys many outdoor activities with his wife and two children.

As our world moves towards a digital transformation, automation is a crucial tool for a thriving business. By automating processes, companies can make their workflows faster and more efficient, enabling them to do more with less. This blog will go over how to automate your label printing and how TEKLYNX can help in providing solutions.

READ MORE

With the right tools and configurations, printing labels from your home office to the factory floor is easy.

READ MORE

One of manufacturing's biggest fears is a product recall - not only because of the potential for bad PR, but because of the wasted product, money, time, and potential safety risks for the users of their products.

READ MORE© Copyright 2024 TEKLYNX CORPORATION SAS. Minden jog fenntartva.

What do you think? Leave us a comment.

Comments will be reviewed and are subject to TEKLYNX’ comment policy. Your email address will not be published publicly.